The Heavy Uncoiler Machine is a special equipment for sheet metal leveling. The body is a welded box-shaped structure. The frequency conversion speed motor drives the drum shaft to provide the main power for the decoiler after decelerating through the gearbox.

![]() Device Description:

Device Description:

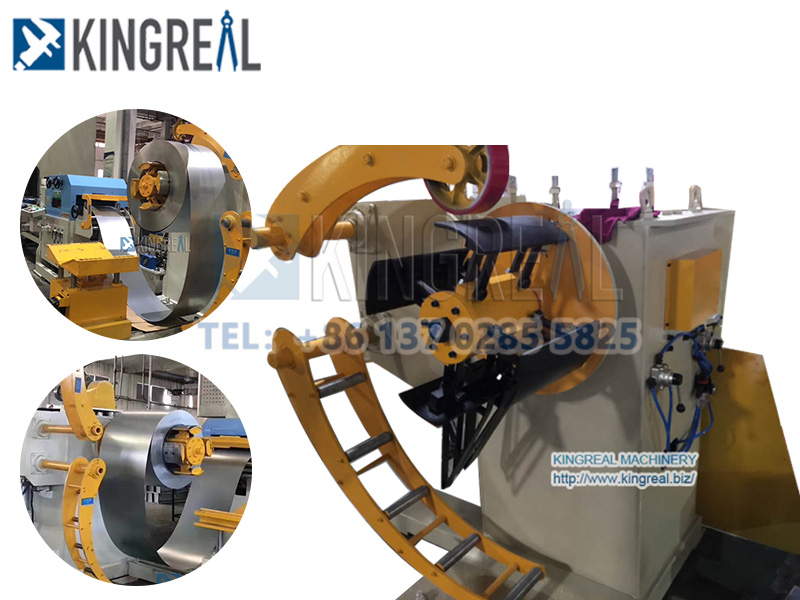

The heavy uncoiler machine is a special equipment for sheet metal leveling. The body is a welded box-shaped structure. The frequency conversion speed motor drives the drum shaft to provide the main power for the decoiler after decelerating through the gearbox. The heavy uncoiler machine is one of the important equipment indispensables in the welded pipe production line. One of its functions is to support the steel coil by tightening the inner hole of the steel coil; Into the leveler.

Therefore, the performance of the uncoiler is very important to the entire production line. In many years of design practice, the structure of the uncoiler has been continuously optimized and improved to improve the performance of the uncoiler.

![]() Product Features:

Product Features:

1. Robustness: exquisite materials, standard welding processing

2. Stability: belt drive, well-known brand electrical components

3. Interchangeability: can be used to switch between unwinding and rewinding

![]() Standard Configuration:

Standard Configuration:

-Hand crank expansion

-4 A-frames

-Touch sensing

Optional configuration:

-Frequency

-Pressing arm

-Hydraulic expansion

![]() Features:

Features:

Safe unwinding process

The heavy-duty decoiler adopts modern electrical control system. The built-in safety protection logic protects the operator‘s safety to the greatest extent. The sturdy mechanical design also ensures stable unwinding performance.

Wide load

The main shaft structure of the heavy-duty decoiler has excellent load-bearing performance and fatigue resistance, and can carry heavier coil weights.

Automatic running

The heavy-duty decoiler is equipped with multiple control arms to realize automatic winding and threading. The function console can manage all processes.

![]() Technical Parameter:

Technical Parameter:

|

Model |

MT-200 |

MT-300 |

MT-400 |

|

Material width [mm] |

0~200 |

0~300 |

0~400 |

|

Material thickness [mm] |

0~2.0 |

0~3.0 |

0~3.0 |

|

Motor [hp] |

1/2 |

1 |

2 |

|

Inner diameter of coil [mm] |

450~530 |

450~530 |

450~530 |

|

Maximum material weight [kg] |

500 |

1000 |

1500 |

|

Machine weight [kg] |

350 |

420 |

450 |