KINGREAL can provide a simple version of the slitting machine, called 200 mm Simple Coil Slitting Machine. It can try to simplify the equipment requirements on the premise that the production line can meet the needs of customers.

KINGREAL as a professional coil processing equipment supplier, can supply metal slitters with any characteristics and cost-effectiveness according to customer requirements. Generally speaking, in order to be able to accurately cut wider coils, the scale of the coil slitting machine production line is relatively large. The corresponding venue and cost will be expensive after all.

However, in order to meet customers with low requirements for accuracy and coil width, KINGREAL will also provide a simple version of the coil slitting machine, called 200 mm Simple Coil Slitting Machine. It can try to simplify the equipment requirements on the premise that the production line can meet the needs of customers.

![]() Parts of Coil Slitting Line

Parts of Coil Slitting Line

The slitting line mainly includes: hydraulic uncoiler, slitting cutter, conveyor, hydraulic winder, tension belt, etc.

The simple version of the slitting line will complete the process of slitting and cutting the coil into the required size, and then rolling it into the specified profile, and the coiler will wind up the scrap steel at the same time.

| Slitting Part It is composed of a side guide device to realize positioning bar and stop jumping bar, bottom frame, knife pivot and movable bracket. Slitting high-quality strip steel is an important part, and different sizes can be adjusted according to the blade. Among them, the cutter shaft is made of Cr-Mo steel, which is precisely manufactured after repeated heat treatment, which can ensure the high precision of the cutting material to the greatest extent. |

|

|

Rewind The overall steel plate cantilever structure design adopts the hydraulic expansion and contraction model design. Hydraulic arm design, equipped with spacers to ensure uniform winding quality. In addition, the front and rear ends of the simple sheet metal slitter are equipped with roller devices to reduce the surface damage of materials. At the same time, it is equipped with a removable control panel for easy operation. |

![]() Features of 200 mm Simple Metal Slitter

Features of 200 mm Simple Metal Slitter

|

1. The steel coil slitting machine has a compact structure, a perfect mechanical hydraulic system and stable operation. 2. The components are all well-known brands and have a long service life. Adopt integrated design to reduce equipment failure rate. 3. Can be customized, design drawings and production machines according to customer needs. |

|

![]() Technical Parameter

Technical Parameter

|

Coil thickness (mm) |

0.4-0.6 |

|

Maximum speed (m/min) |

20 |

|

Number of slitting machines |

Tailored |

|

Roller stand |

18 |

|

Main power (Kw) |

7.5 |

|

Spindle (mm) |

Ø70 |

|

Tool material |

Cr12 |

|

Cutting accuracy |

10±2mm |

|

Hydraulic station power (Kw) |

5.5 |

|

Control system |

Programmable logic controller |

![]() Other Coil Slitting Line KINGREAL can Provide

Other Coil Slitting Line KINGREAL can Provide

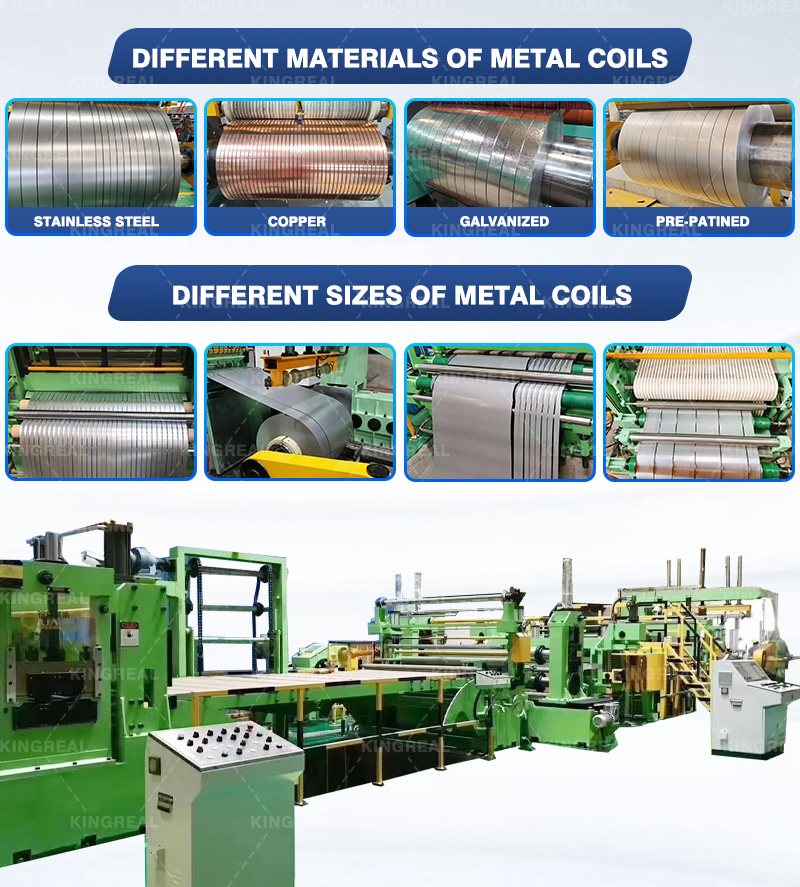

| 1. Heavy Gauge Slitting Line Machine 2. Hot Roll Steel Coil Slitting Line 3. Dual Slitter Head Coil Slitting Machine 4. Combined Slitting and Cut To Length line |

|

![]() Different Coil Slitting Machine solution

Different Coil Slitting Machine solution

![]() Installation Service

Installation Service

In order to help our customers solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange for engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

KINGREAL After-sales Installation Team