The silicon steel coil slitting machine is a special equipment for cutting metal coil and other metal sheet into strips of a certain width.

As a manufacturer focusing on the production of slitting machines for more than 20 years, KINGREAL can design customized steel slitters according to the different needs of customers.

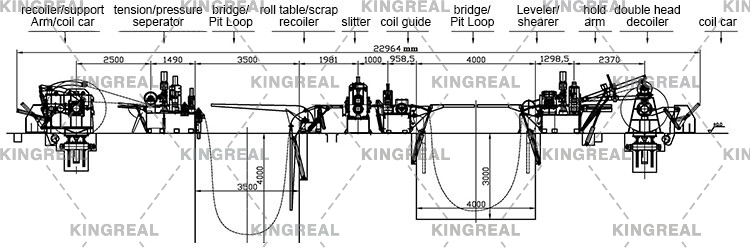

| No. | Name | Quantity |

| 1 | Material coil table | 1 unit |

| 2 | Coil Load Trolley | 1 unit |

| 3 | Hydraulic decoiler | 1 set |

| 4 | Material feeder, pinch roller and hydraulic shearing | 1 set |

| 5 | Loop bridge | 1 set |

| 6 | Manual side gudie and pinch feeding | 1 set |

| 7 | Main slitting machine | 1 unit |

| 8 | Splicing rack and trimmer with scrap colletcor | 1 set |

| 9 | Loop bridge | 1 set |

| 10 | Seperator, tension station | 1 set |

| 11 | Separators, uncoiler and punshing material device | 1 set |

| 12 | Hydraulic support | 1set |

| 13 | Unloading trolley | 1 set |

| 14 | Hydraulic system | 1 set |

| 15 | Eletronic control system | 1 set |

| 16 | Lubrication system | 1 set |

| 17 | Pneumatic system | 1 set |

| 18 | Spare parts | 1 set |

| Material : Silicon (other can be customized) Coil Thickness : 0.3-3mm Coil Width : 500-1600(Max) Max Coil Weight : 20 T Slitting Machine Speed : 0-220m/min |

| 1. The equipment adopts advanced pulling and shearing technology. High precision of sheet shearing. 2. The tool axis adopts high precision machine tool spindle with main bearing support. Less runout in axial and diameter direction. 3. The tool plate adopts a three-point positioning and locking method, with high dimensional accuracy and reliable locking. |

double slitter head |

decoiler trolley |