Kingreal is a veteran coil slitting machine manufacturer in China. We have been in the coil slitting-metal sheet cut to length industry for more than 20 years and have set up our own factory and technical team, which can provide high quality slit coil equipment.

2. All DC motors are equipped with off-line setting, push button slitting tool lock, power indexing tension roller, quick change tool lever and automatic transmission.

3. Several design elements of this roll slitting line improve high yield output, including slit edge quality, straight wall slitting rolls, and the ability to maintain tight slit tape tolerances.

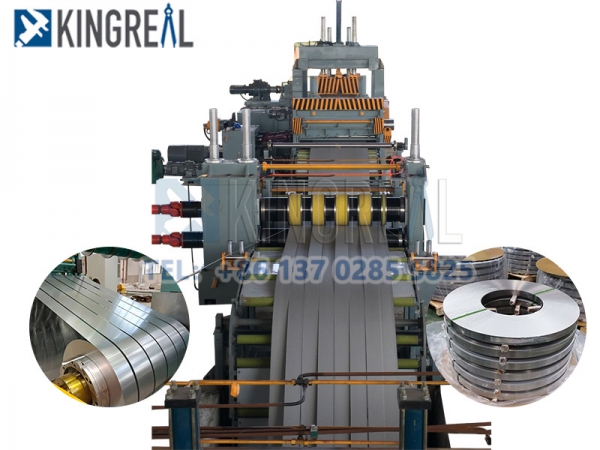

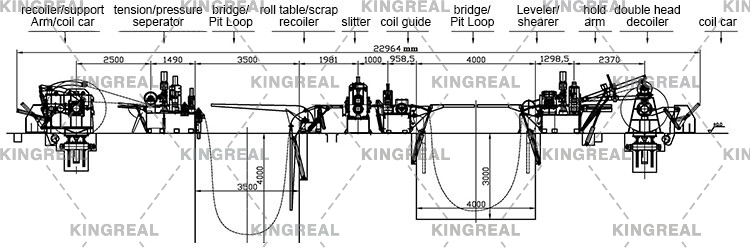

![]() Composition of Coil Slitting Line Machine

Composition of Coil Slitting Line Machine

Backup Saddle --- Hydraulic Trolley --- Hydraulic Double-head Decoiler --- Unwinding and Unwinding machine --- Pinch Leveling Shearing Machine --- Lifting Loop --- Guide and Nip Roll Machine --- Slitting Machine --- Edge Wire Machine --- Loop Bridge --- Tension Generating Station --- Hydraulic Rewinder

![]() What Can KINGREAL Metal Slitter Provide

What Can KINGREAL Metal Slitter Provide

| Controlled by the electrical control system -- the key to improving precision Adopt imported servo motor -- low failure rate and long life The feed length can be set at any length -- high production flexibility |

|

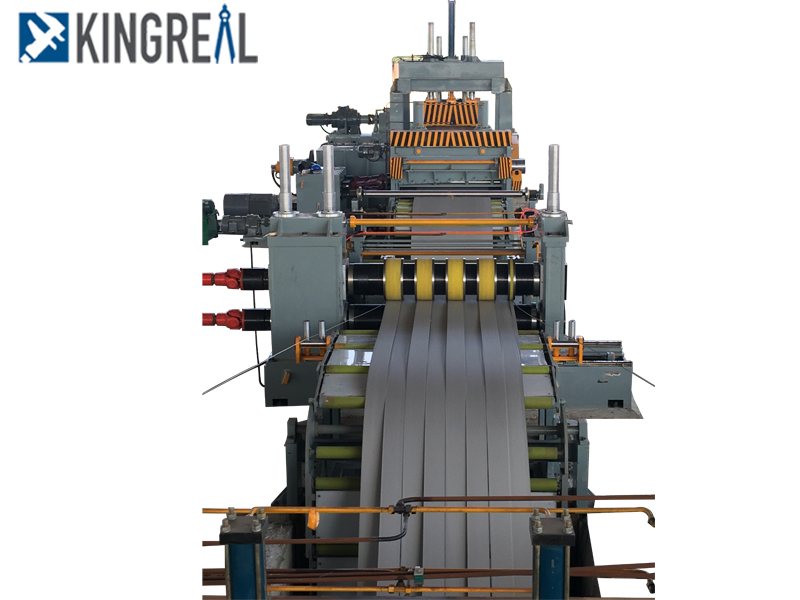

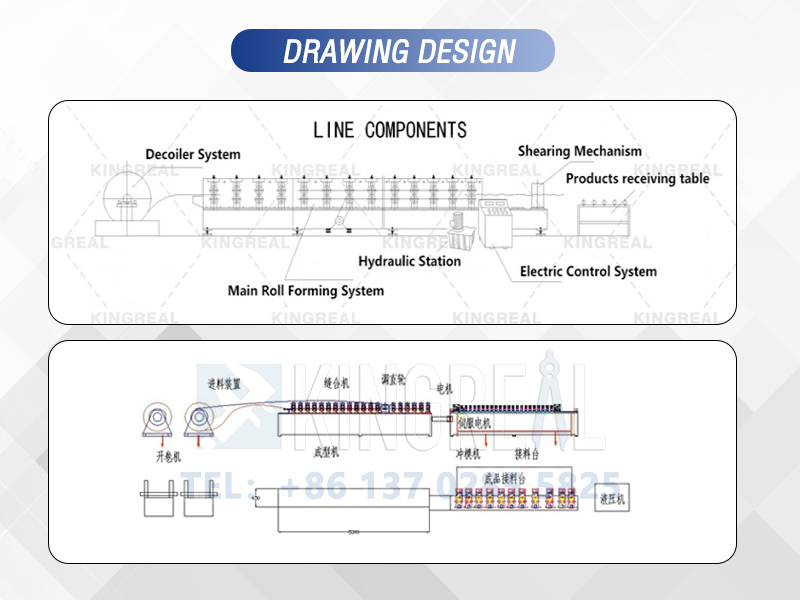

![]() Features of Components of Middle-plate Coil Slitting Machine

Features of Components of Middle-plate Coil Slitting Machine

1. Decoiler

Double mandrel structure, clamping the coil on the center line. The double mandrel can be conical or three-step conical. Center alignment is driven by hydraulic cylinders on the base of each decoiler.

2. Slitting machine:

Powerful double-spindle circular slitting knife. Material: 40Cr, forged and tempered, intermediate frequency quenched, hard chrome plated, finely polished.

3. Tension:

Felt or five-roller type is tension according to the strength of the steel strip material, which is reliable and stable.

|

|

4. Rewind:

DC motor and gear box reduces the drive to drive the coiling mandrel, with an arm separator or portal press separator.

5. Electrical control system:

PLC control system, using a man-machine interface, the operation is more convenient.

![]() Ingredient Parameters

Ingredient Parameters

| Material | all series of stainless steel |

| Material thickness | 1.2-6.0mm |

| Roll weight | 25 tons |

| Material width | 800-1700mm |

![]() Finished Product Parameters

Finished Product Parameters

| Number of strips | 1.2-4.0mm, up to 14, 5.1-8.0 up to 8 |

| Slit straightness | ±0.02mm |

| Width tolerance | ±0.02mm |

| Tool shaft transfer | ±0.03mm |

| Linear speed | 100m/min |

| Operator Requirements | 1 mechanic, 2 auxiliary workers |

![]() FAQ

FAQ

1. What are our advantages?

With more than 15 years experience in manufacturing the machines and we are a manufacturer.

So we can provide a strong and powerful service before and after sales.

2. How to visit your company?

Our factory is located in Foshan City, Guangdong Province. So there are two ways to our city.

3. What information do you have to provide for us to prepare a quote?

1. Thickness of the coil (min-max)?

2. Coil width (min-max)?

3. What is your steel material?

4. Coil weight (max)?

5. How many pieces of maximum thickness do you need to slit?

6. How many tons do you need per day or per month?

|

|

![]() KINGREAL in Diverse Exhibitions

KINGREAL in Diverse Exhibitions