The slitting speed of KINGREAL High Speed Coil Slitting Line Machine can be up to 220m/min, definitely meeting your demand for slitting efficiency. As a manufacturer focusing on the production of metal slitters for more than 20 years, KINGREAL can design customized slitting lines according to the different needs of customers.

| No. | Name | Qty. |

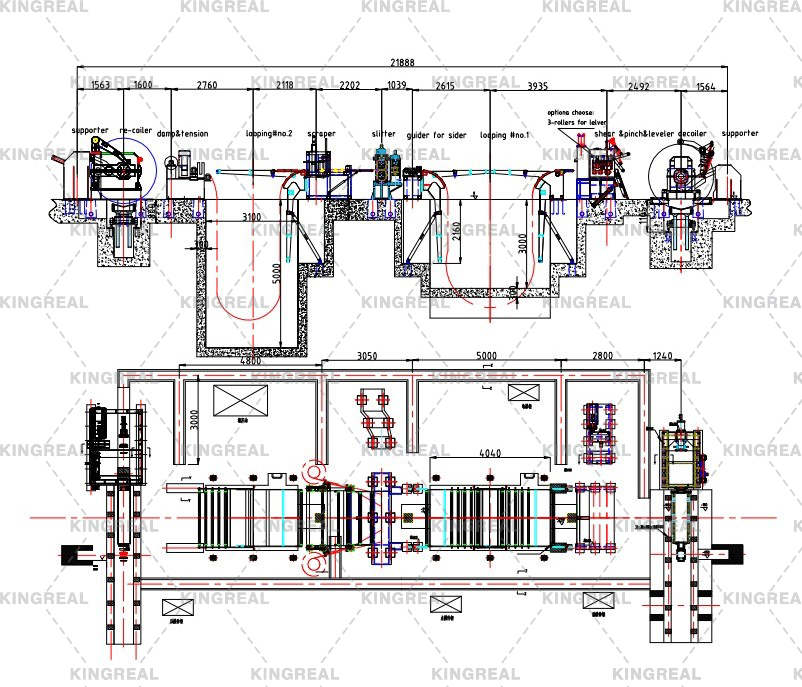

| 1 | Material storage table(optional) | 1 pair |

| 2 | Feeding trolley | 1 set |

| 3 | Double cone Uncoiler + Recoiler | 1 set |

| 4 | 1# Bridge | 1 set |

| 5 | Guiding device | 1 set |

| 6 | Slitting machine | 1 set |

| 7 | Material transition device | 1 set |

| 8 | Integral edge trimmer | 1 set |

| 9 | 2#Bridge | 1 set |

| 10 | Tensioner | 1 set |

| 11 | Winding machine (with separating frame) | 1 set |

| 12 | Unloading trolley | 1 set |

| 13 | Hydraulic system | 2 sets |

| 14 | Pneumatic system | 1 set |

| Material | Carbon Steel CR HRPO SS304, SS316 |

| Thickness | 0.3-3.0mm |

| Material width | 100-850mm |

| Maxweight of coil | 12T |

| Slitting speed | up to 220m/min |

| - Adopting double head slitter blade design, users can quickly and conveniently replace the slitter blades, bringing more efficient slitting operations. - KINGREAL provides the trolley for loading the heavy steel coil, It not only makes the unwinding process more convenient, but also greatly speeds up the slitting preparation work. - This steel coil slitting line machine is controlled by PLC, with high automation, high shearing precision and good slitting quality. |

|

![]() Other Featuring Coil Slitting Machine in KINGREAL

Other Featuring Coil Slitting Machine in KINGREAL

|