KINGREAL can provide a Copper Coil Slitting Machine for precisely slitting the copper coil. As a manufacturer focusing on the production of metal slitting machines for more than 20 years, KINGREAL can design customized coil slitters according to the different needs of customers.

![]() Description of Copper Slitting Line Machine

Description of Copper Slitting Line Machine

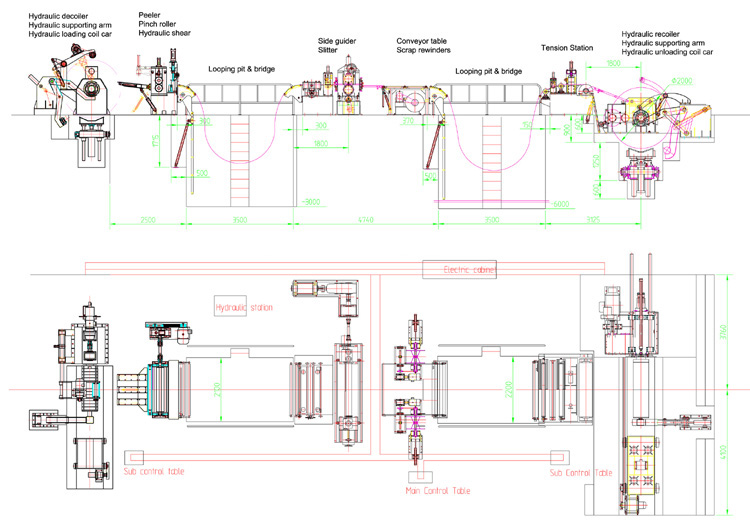

The Production of copper slitting line machine is a continuous slitting production line in which the wide coil is opened by the recoiler, the coil is cut into a specific width by the slitting machine, and finally wound into several coils by the winder.

KINGREAL copper coil slitter is a remarkable piece of equipment that is designed to effortlessly slit metal coil into precisely narrow strips, it is the high economic benefits equipment for metal coil slitting industry.

![]() Working Process of Copper Coil Slitter

Working Process of Copper Coil Slitter

Coil loading Trolley → Hydraulic Decoiler → Pinch Straightener → Pit Loop → Coil Side Guider → Guide Align / Disc Slitting → Side Scrap Collector → Pit Loops → Tensioner → Rewinder Machine → Coils Unloading → Finished Products

![]() Specifications of Copper Coil Slitter

Specifications of Copper Coil Slitter

|

Processing material |

Cold rolled copper coil |

|

Maximum tensile strength |

Consider ultimate strength 80kg/mm2 |

|

Maximum yield strength |

60kg/mm2 |

|

Plate thickness |

0.1mm-1.2mm |

|

Board pair |

310mm-680mm |

|

Coil outer diameter |

Φ1600mm |

|

Inner diameter of coil |

Φ500mm |

|

Coil weight |

10000kg |

|

Rewinding outer diameter |

Φ1500mm |

|

Rewinding inner diameter |

Φ250, Φ300, Φ400, Φ500 |

|

Winder load |

Maximum 10000kg |

![]() Features of Copper Slitting Line Machine

Features of Copper Slitting Line Machine

| High-quality precision The guide device is mainly composed of left and right sliders, worm gears and worms. Using the slider structure can greatly reduce the gap of the guide mechanism, so that the axial movement of the main shaft is less than 0.1mm, and the radial gap is also less than 0.03mm. The stability of the spindle is improved, and the shearing accuracy is guaranteed. |

|

|

Easy operation The sliding seat can be moved on the base with the sliding rail driven by the motor, which is convenient to replace the cutter head, cutter pad and spacer. The upper and lower cutter shafts are respectively supported in the two bushings on the movable support of the frame and the fixed support, and the cutting amount of the blade can be adjusted by adjusting the worm gear and worm to change the distance between the cutter shafts. |

| Long service life The base part mainly includes a fixed base, a movable base, and a motor bracket. It is welded by steel plate, and the aging treatment after welding has good rigidity and no deformation. |

|

![]() Application of Copper Coil

Application of Copper Coil

| - Electronic communications - Household appliances - Transportation - Energy storage - Electricity |

|

![]() Other Featuring Coil Slitting Machine in KINGREAL

Other Featuring Coil Slitting Machine in KINGREAL

| Dual Slitter Head Coil Slitting Machine Hot Roll Coil Slitter Heavy Gauge Slitting Line Machine Thin Plate Coil Slitting Machine |

|

![]() Installation Service

Installation Service

In order to help our customers solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange for engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

![]() Customer Visit

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL warmly welcomes customers to visit our factory and communicate with us!