Swing beam shearing is is one of the shearing processes of the coil cut to length line. KINGREAL can provide different types of coil cut to length lines according to your different production needs. You only need to tell us your requirements and we will customize the suitable solution for you.

![]() Description of Swing Beam Cut to Length Line Machine

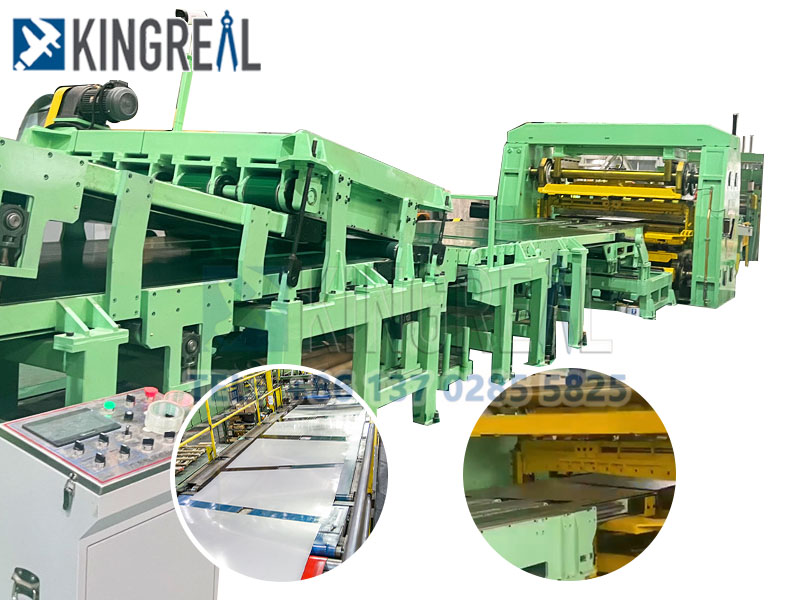

Description of Swing Beam Cut to Length Line Machine

Swing beam cut to length line machine is a kind of sheet metal cutting equipment widely used in machining, which can cut out sheet metal of various thicknesses. Swing beam shearing is one of the shearing processes in the coil cut to length line. It is favored by many metal sheet cutting manufacturers for its special cutting surface. Compared with the common fix station coil cut to length line, the swing beam cut to length line machine has a faster cutting speed, which can reach 80m/min.

![]() Main Working Process

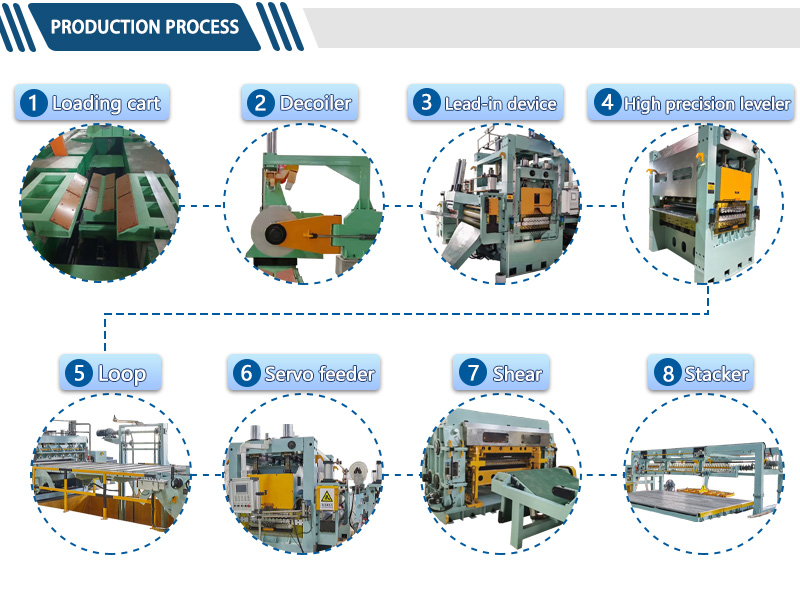

Main Working Process

Hydraulic Decoiler -- Pinch&Straightener -- Servo Cut Length -- Rotary Shearing Machine -- Conveyor Belt --Auto Stack

![]() Specification

Specification

| Raw Material | Steel/Aluminum/CR/HR |

| Coil Thickness | 0.3-3MM |

| Coil Width | 400-1600 |

| Coil Weight | 20 Ton |

| Cutting Accurate | ±0.3MM |

| Working Speed | 80M/Min |

| Number Of Shears | 150PS |

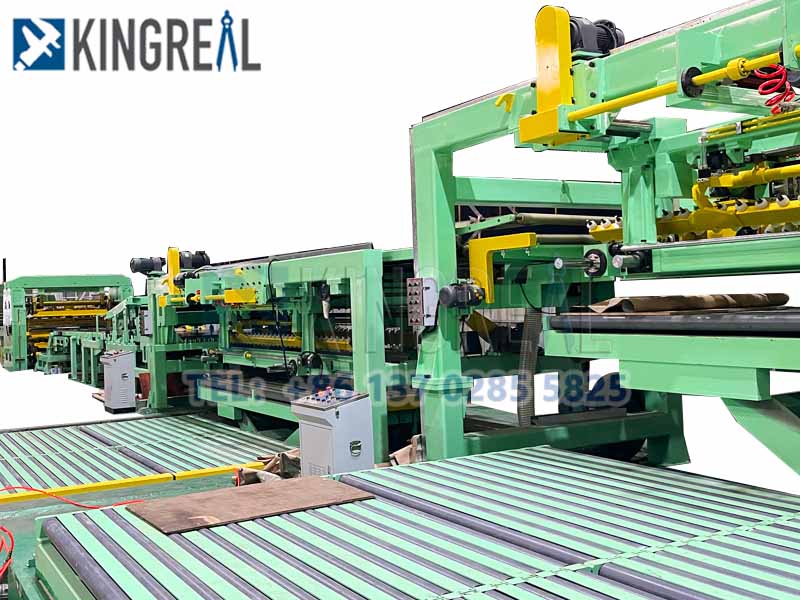

![]() Details of CTL Line Components

Details of CTL Line Components

Precision Leveler

- Multi-roller leveling eliminates unevenness of metal sheets or strips during the raw material production process.

- Ensure that metal sheets or strips maintain good straightness before and after shearing, also avoid bending of the material and affecting subsequent processing. Flat materials help to cut flat cuts during the rotary cutting process and improve the accuracy of the overall process.

Cutting Process

By choosing the new and improved CNC swing follow shears , customers can experience a modern technology with maximum safety, high precision and unique ease of use.

And the blade gap and cut to length are automatically adjusted according to material selection and thickness.

Uniform rotating shear gap: the uniform gap of the rotary shear helps to improve the stability of the shear, reduce the loss of the mold and extend the life of the machine.

Pneumatic sheet support system

Integral panel support system:

![]() What can Swing Beam Cut to Length Line Machine Provide

What can Swing Beam Cut to Length Line Machine Provide

| 1. It adopts steel plate welded structure, hydraulic transmission, nitrogen cylinder return, easy operation, reliable performance and beautiful appearance. 2. There are signs for the adjustment of the cutting edge gap, and the adjustment is light and fast. 3. It is equipped with a light-to-line lighting device, and can sleeplessly adjust the stroke of the upper tool rest. 4. The work area adopts the fence type personal safety protection device. 5. There is a digital device for the size of the back gauge and the number of shears. |

|

![]() Advantage of Rotary Shear Cut to Length Line

Advantage of Rotary Shear Cut to Length Line

1. Hydraulic transmission, pendulum tool rest, the overall welding of the frame is sturdy and durable, and the return stroke of the accumulator cylinder is stable and fast.

2. It has the function of adjustment of the stroke. The upper knife has two blades, and the lower knife has four blades. The gap between the upper and lower blades is adjusted by the handle, and the uniformity of the blade gap is easy to adjust.

3. The protective grille and electrical interlock ensure safe operation.

![]() Other Optional Coil Cut to Length Line

Other Optional Coil Cut to Length Line

| - Fly Shearing Coil Cut to Length Machine - Fix Station Coil Cut to Length Line |

|

![]() KINGREAL Successful Coil Cut to Length Machine Projects

KINGREAL Successful Coil Cut to Length Machine Projects

![]() Order Process

Order Process