How does a steel slitter work?

As the domestic market and relevant developing countries abroad emphasize infrastructure and civilian technology, the global manufacturing industry continues to evolve. Processing related materials is an essential part of this process, which includes the slitting of various materials. Coil Slitting machines have thus become indispensable equipment. A steel slitting machine generally consists of equipment for unwinding, feeding, longitudinal cutting, and rewinding. KINGREAL is a professional manufacturer of coil slitting machines. If you have any questions, feel free to consult us!

A steel slitting machine is a device used for longitudinally cutting metal coil materials, such as slitting strip steel, stainless steel, copper strips, aluminum foil, etc. It is primarily used in steel processing manufacturers (steel market operators, rolling mills, electrical industries, automotive, stamping parts, etc.). Unlike conventional cutting equipment, this machine performs a novel, infinite length cutting action by rolling circular blades across the sheet material.

Types

1. Single Machine Steel Slitting Machine: A compact machine with builtin rewinding, generally used for small rolls.

2. Combination Steel Slitting Machine: Composed of an unwinding rack, steel slitting machine, and rewinding machine, suitable for larger rolls.

Cutting Principle

Cutting Action: Longitudinal cutting is essentially a shearing operation. The metal sheet is cut longitudinally by a set of rotating blades, similar to the operation of scissors.

Width Control: The distance between the blades determines the width of the resulting slitting coil. Therefore, the precise positioning of the blades is crucial for achieving the desired width.

Tension Management: Proper tension management is essential to maintain the flatness and edge quality of the slitting material. Too much or too little tension can lead to issues such as curvature, burrs, or wavy edges.

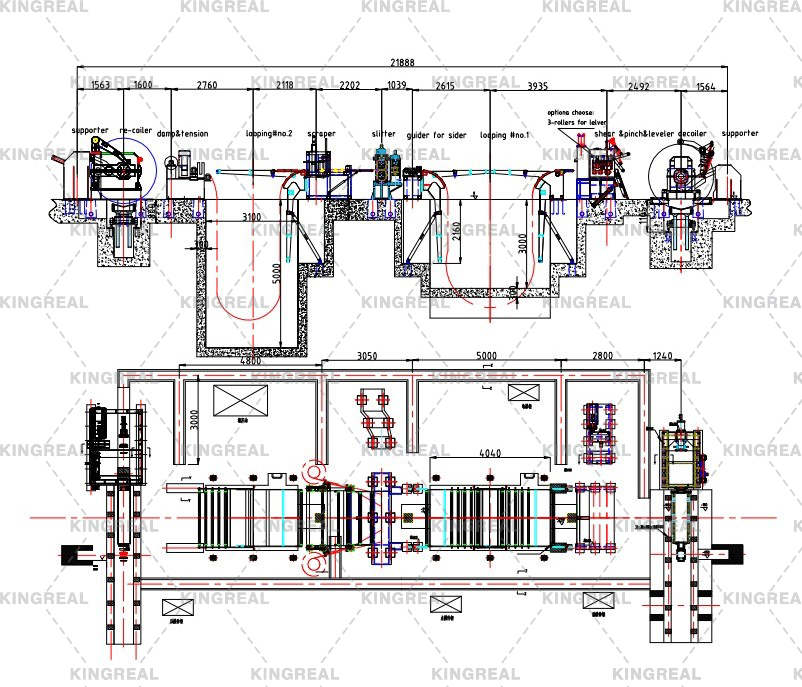

Upload material -- Decoiler -- Clip feed leveler/shearer -- First Loop bridge -- Guide and Slitting -- Scrap collection -- Second Loop bridge -- Tension machine -- Uncoiler slitted coil -- Unload Coils

Configuring the Steel Slitting Machine

Configuring the coil slitting machine is a key step to ensure the accuracy and consistency of the entire slitting process.

1. Blade Positioning: The first and most important task is to position the slitting blades. The blades need to be arranged according to the expected width of the slitting coil. This is a precise task requiring accuracy, as even a small deviation can lead to incorrect width.

Desired Width: The width of the resulting coil determines the distance between the blades.

Material Thickness: Thicker materials may require slight adjustments to blade positions to address deflection issues.

Blade Diameter: Larger diameter blades may require greater spacing to prevent interference.

2. Setting Tension: Next, the tension settings for the unwinding and rewinding machines need to be adjusted. The tension must be just right—too high can stretch or warp the material; too low can result in uneven slitting or loose winding of coils.

Unwinding Tension: Should be set to maintain a consistent, stable feed rate without stretching the material.

Rewinding Tension: Must be high enough to tightly wind the slitting coil but not so high that it causes stretching or warping.

Tips for Successful Slitting Operations

Slitting operations require meticulous planning and execution for success. Here are some tips:

Regular Maintenance: Regular maintenance of the slitting machine can prevent many problems and ensure consistent, high-quality slitting.

Proper Material Handling: Correct handling of metal sheets before, during, and after slitting can prevent defects and ensure high-quality slitting coils.

Continuous Monitoring: Ongoing monitoring of slitting operations helps identify and correct issues early, preventing defects and waste.

Continuous Improvement: Regularly reviewing and improving the slitting process can enhance efficiency, improve product quality, and reduce costs.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima