How many types of slitting are there?

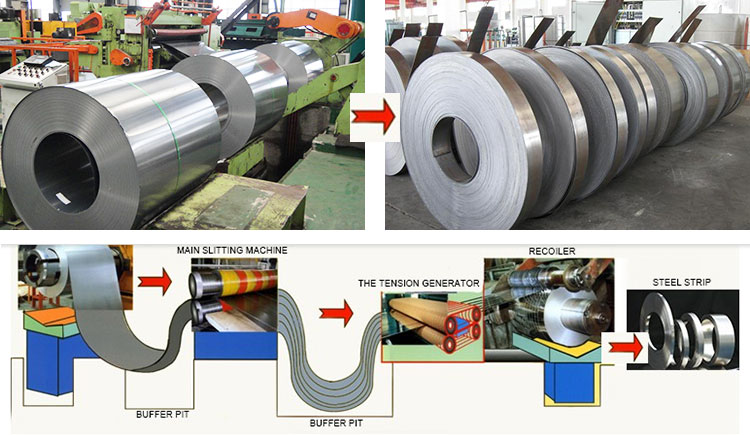

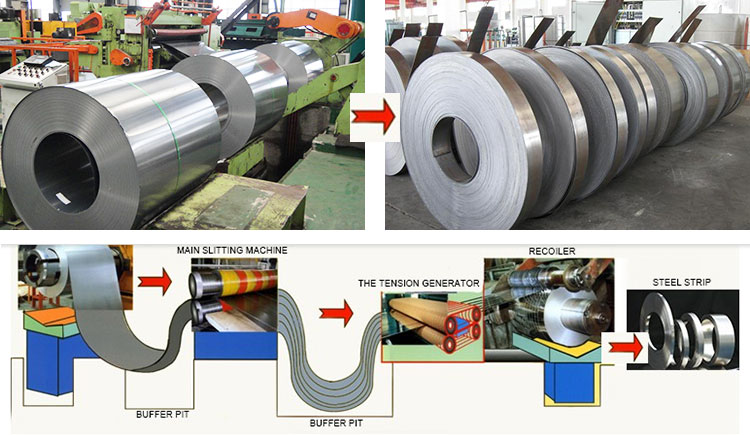

Coil slitting machines, also known as coil slitter machines, are widely used in industrial production to cut wide rolls of material into multiple narrower strips. These materials can include paper, plastic, metal foil, and more. The design and operation of coil slitting equipment are crucial for ensuring cutting quality and production efficiency. KINGREAL is a professional slitting line manufacturer. If you have any questions, please come to consult!

This article will explore the different cutting methods of slitter machines in detail and discuss their importance in industrial applications.

1. Mechanical Slitting Methods

Mechanical slitting machines typically use various tools and cutting mechanisms to achieve material division. Common mechanical slitting methods include:

Blade slitting, or rotary slitting, is one of the most common methods. It uses rotating blades or knives to cut the material. The advantage of blade slitting line is its high cutting precision, making it suitable for processing materials of varying thickness. The blades are usually made from high-hardness materials to ensure durability and long-term use. This method is suitable for slitting paper, films, plastics, and other materials.

Circular knife slitting involves using a set of fixed circular knives to cut the material. This method is suitable for thicker materials, such as metal foils and cardboard. The main advantage of circular knife slitting is its ability to provide consistent cutting widths and is suitable for high-speed production lines.

2. Laser Slitting Methods

Laser slitting machines use laser beams to precisely cut materials. Laser slitting offers extremely high cutting precision and smooth edges, making it ideal for high-end applications and complex shapes. The advantages of laser slitting include:

High Precision: Lasers can control the cutting path with exceptional accuracy, making them suitable for applications that require extremely high precision.

Non-Contact Cutting: Laser cutting is a non-contact process, reducing mechanical stress on the material and allowing for the processing of very thin materials.

Complex Shapes Adaptation: Laser cutting can achieve intricate designs and details, making it suitable for the production of high-precision custom products.

3. Cutting and Shearing Combined Methods

This method combines cutting and shearing features and is used for handling thicker materials. It typically includes:

Shearing Blade Slitting: Shearing blades use mechanical pressure to cut the material. This method is suitable for handling thicker materials, such as certain metals and composite materials.

Cutting and Peeling Combination: This technique combines slitting with peeling to handle complex material structures and provides an efficient production method.

.jpg)

Conclusion

There are many coil slitting machine line methods available, each suited to different types of materials and production needs. Blade slitting and circular knife slitting are versatile for handling a range of materials and thicknesses, while laser slitting offers high precision and the ability to handle complex shapes. Cutting and shearing combined methods are suitable for thicker materials. Understanding these slitting methods helps in selecting the appropriate equipment to meet specific production requirements.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima