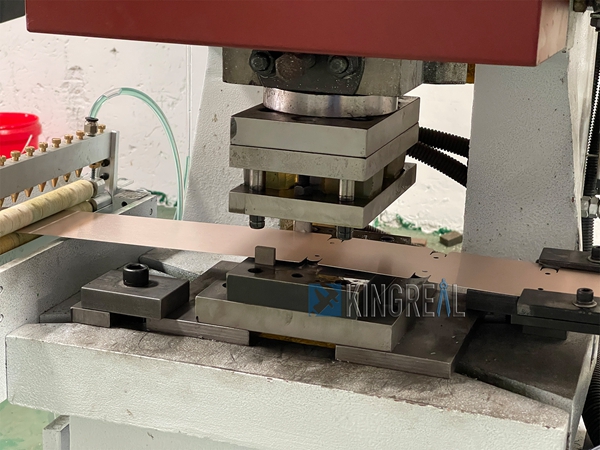

How to adjust the level of the punch?

The punching machine must be kept level when processing, so that the work-piece can be more precise.

What should be paid attention to when adjusting the level?

KINGREAL will provide a brief introduction for you:

1. There is no need to feed the material during adjustment, but first raise the guide screw on the guide plate. Then use the inch method to slowly adjust the punch hammer to the bottom dead center. It is also important to note that the guide plate cannot depress the floating rod too low, otherwise the floating rod will be bent or broken.

When starting the punch feeder for continuous punching, the speed adjustment screw of the feeder must be rotated clockwise, and the slider moves slowly, so that is can be recognized whether the nylon gasket and the length fine-tuning screw are encountered when the slider moves back and forth.

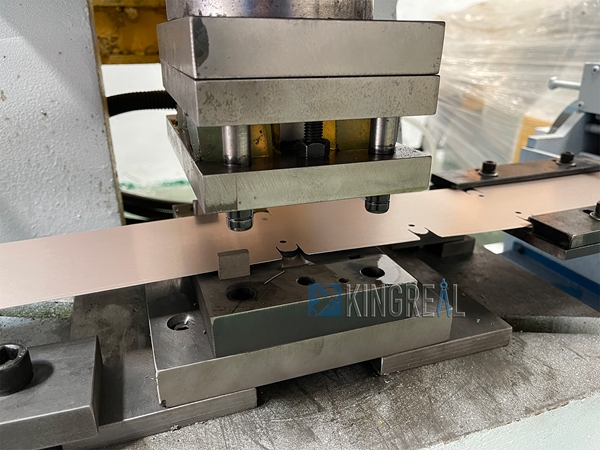

2. During the test run, the slider moves back and forth. If it only touches the nylon gasket and does not touch the fine-tuning screw, it means that the floating rod is not lowered deeply enough. The guide screw on the side of the punch should be lowered slowly.

If the slider moves back and forth, only the length fine-tuning screw does not touch the nylon gasket, it is because the floating rod descends too deep, and the guide screw on the side of the punch needs to be slowly raised.

3. If the slider moves between the length fine-tuning screw and the nylon gasket and the distances on both sides are equal, at this time, adjust the screw in a counterclockwise direction, so that the slider speed is normal, and the slider can be touched when it moves back and forth. Nylon spacer and spacer ring.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima