What are the parts of a coil slitter?

In manufacturing, especially when working with sheet metal, precise cutting is crucial. One technique used to achieve this is slitting. This process is an important aspect of sheet metal fabrication, allowing for the effective sizing and shaping of metal for various applications. From manufacturing HVAC components to automotive parts, the role of coil slitting operations in sheet metal fabrication is significant and merits thorough exploration.

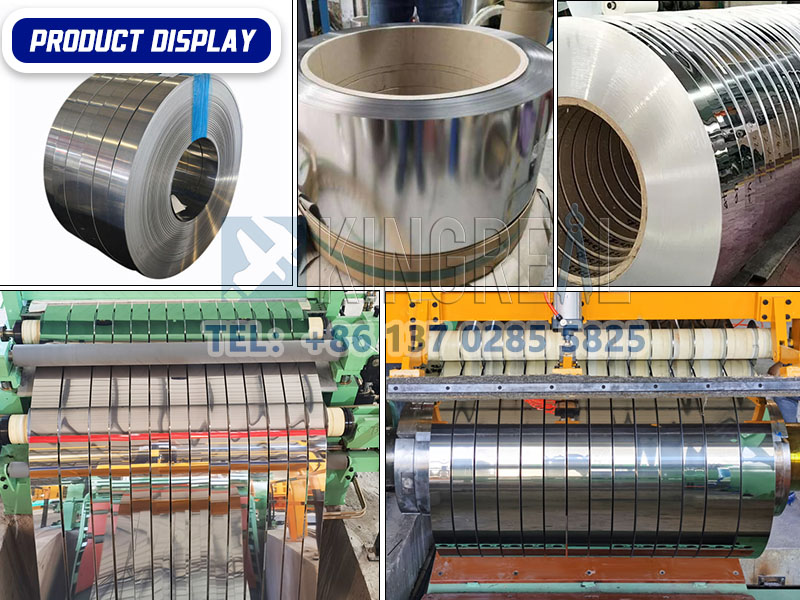

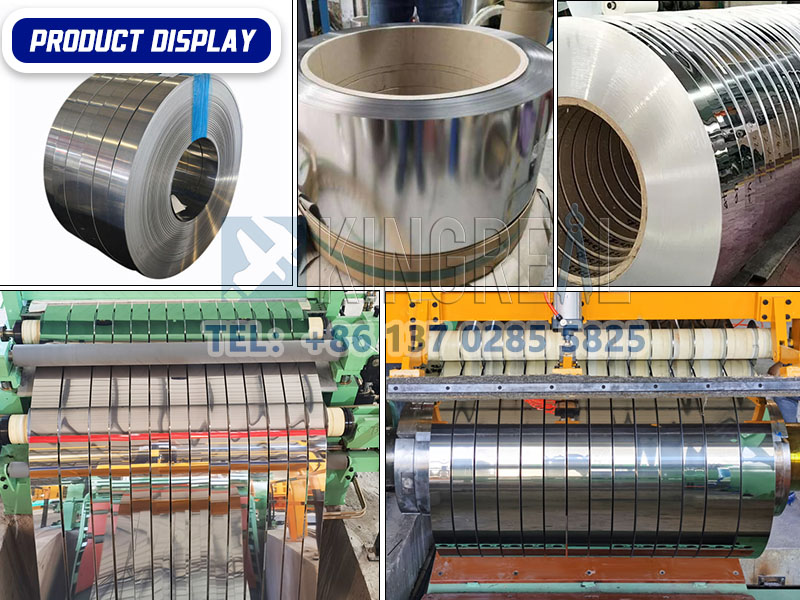

Coil slitting involves cutting large coils of metal raw material into narrower coils. The narrower coils are known as "slit coils," and the machine used to perform the coil slitting process is called a "coil slitting machine."

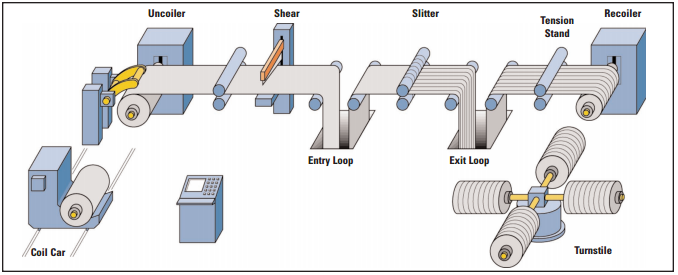

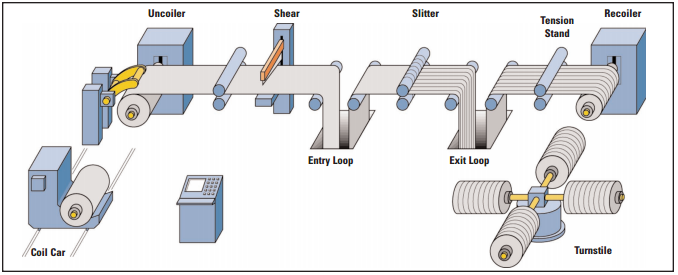

Process Flow

Loading Trolley -- Decoiler -- Roller Feeding -- Loop -- Slitting -- Waste Wire Machine -- Loop -- Separator -- Winder -- Unloading Car

Main components of a coil slitting machine

1. Frame and Drive System

Frame: Typically consists of left and right side plates, support blocks, and uncoiling machinery, providing structural support for the entire coil slitting machine.

Drive System: Primarily used to pull the raw material and wind the finished product. This system includes a variable frequency drive motor that transmits power through the motor, with a shaped belt driving the traction rubber rollers. The main and auxiliary traction rubber rollers are in close contact to move the raw material synchronously.

2. Rewinding Mechanism and Tension Device

Rewinding Mechanism: Mainly composed of synchronous belts, synchronous wheels, magnetic powder clutches, and air-expansion shafts. The main power is transmitted from the synchronous belt to the synchronous wheel, which then drives the input shaft of the magnetic powder clutch to perform the rewinding function.

Tension Device: Used to adjust and control the tension during the rewinding process, ensuring that the material is wound evenly and tightly.

3. Pulling Components

Pulling Components: Mainly consist of a pair of traction rubber rollers and several hard alumina rollers used to pull the raw material into finished coils. Power is transmitted from the motor to the driver via a V-belt, driving the rubber rollers.

4. Coil Slitting System

Slitting Knife Frame: One of the core components of the coil slitter, used to cut the material into the desired strip width. The slitting knife frame can use either circular or straight knives, with the circular knife‘s position adjustable via a handle to change the cutting width.

Cutting Tools: Typically made from hard alloys or high-speed steel, these tools offer good wear resistance and cutting performance. The cutting device secures the cutting tools and controls the cutting speed and thickness.

5. Waste Handling System

Used to handle waste produced during the cutting process. For example, waste can be expelled through air ducts using the energy of a blower, maintaining a clean working environment.

6. Control System

The control system is the "brain" of the coil slitting machine, managing the operation of the machine and adjusting cutting parameters (such as cutting speed and tension) to ensure cutting quality and efficiency. Modern coil slitters typically use advanced PLC or CNC control systems for automation and precise control.

In summary, the main components of a coil slitting machine include the frame and drive system, rewinding mechanism and tension device, pulling components, coil slitting system (including the slitting knife frame and cutting tools), waste handling system, and control system. These components work together to achieve the cutting function of the coil slitting machine.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima