What is a coil slitting blade?

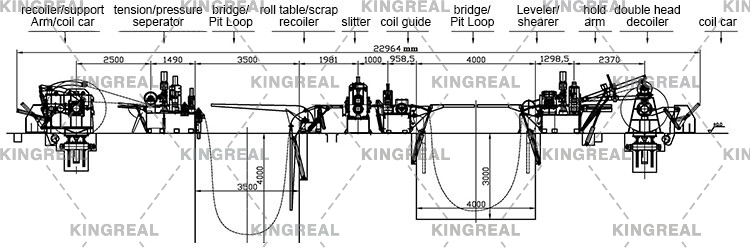

The coil slitting machine is a type of metal processing equipment primarily used to slit metal coils into strips of specified widths. It consists of components such as a feeding car, uncoiler, leveler, coil slitter, edge trim collector, tensioner, recoiler, and unloading device.

During operation, blades are used to slit the metal material. Proper blade adjustment is crucial for production efficiency and cutting quality. Ideal coil slitting knife gaps can extend blade life, improve coil slitting quality, reduce defect rates, and lower production costs. Achieving the optimal blade gap requires precision coil slitting machines and high-accuracy steel sleeves to maintain consistent gaps during high-speed cutting. This document provides a detailed introduction to coil slitting knives.

Introduction

Coil slitting knives are also known as: steel slitting knives, rotary knives, shear slitting knives, circular metal slitting knives, rotary shear blades, metal slitting blades, and roll shear knives.

Dimensions: Custom-made for your coil slitter.

Materials: High-alloy tool steel, high-speed steel, high-toughness and wear-resistant special alloy steel, or as per customer requirements.

Hardness: Recommended hardness specifications based on material grade or customer requirements.

Applications: Coil slitting and trimming of cold, hot, stainless, and non-ferrous alloys.

Machines: Coil slitting lines, length-cutting lines, metal processing machines, and sheet metal slitters.

Adjusting methods of upper and lower knives on metal slitting machine

Before adjusting the upper and lower knives, ensure the following preparations:

(1) Check the equipment’s power and air pressure connections.

(2) Confirm the sharpness of the blades; replace them if necessary.

(3) Verify that the metal material to be processed meets the required specifications, such as type and thickness.

Adjusting the upper knife:

(1) Place the metal material on the workbench and lower the upper knife to a suitable position above the material, ensuring it is parallel to the workbench.

(2) Adjust the gap between the upper and lower knives by moving the upper knife horizontally, based on the material thickness and coil slitting requirements.

(3) Adjust the vertical position of the upper knife to ensure clean cuts without delamination.

Adjusting the lower knife:

(1) Ensure the gap between the lower knife and the upper knife is appropriate, and the lower knife is parallel to the workbench.

(2) Adjust the lower knife’s position using horizontal and vertical adjustment devices.

(3) Check the sharpness of the lower knife, and replace or sharpen if needed.

After completing the adjustments, perform test cuts and inspections to ensure the quality and effectiveness of the adjustments. Regular maintenance and upkeep of the equipment are necessary to ensure proper operation and extend the machine’s lifespan. Proper adjustment methods can enhance production efficiency, reduce metal delamination and burrs, and improve product quality and market competitiveness.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima