What are the problems of coil slitting?

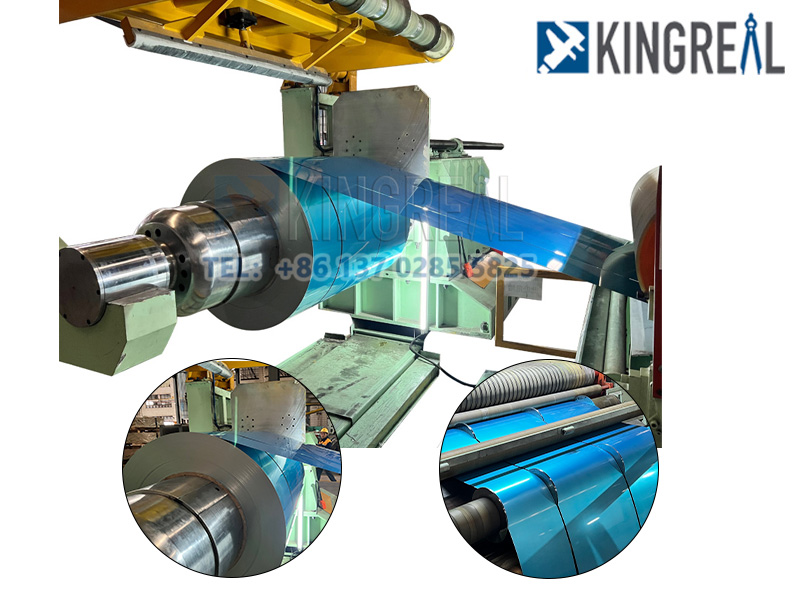

A coil slitting machine is a device used to longitudinally cut metal raw materials into multiple strips of the desired specifications. It is primarily composed of components such as the feeding trolley, uncoiler, leveler, coil slitter, edge trim recoiler, tensioner, recoiler, and unloading device.

During the operation of the machine, some common issues may arise, causing difficulties for operators. In this article, I will summarize two common problems encountered with coil slitting machines, hoping it will be helpful to you.

During the operation of the machine, some common issues may arise, causing difficulties for operators. In this article, I will summarize two common problems encountered with coil slitting machines, hoping it will be helpful to you.

1.Uneven Cutting

To avoid uneven cutting, consider the following aspects:

(1) Equipment

Regular Maintenance and Calibration: Ensure that the cutting blades of the machine are sharp and not worn. Worn blades can lead to uneven cutting force, causing irregular cuts. For example, with saw blades, regularly check for wear and replace severely worn blades in a timely manner. Additionally, calibrate the equipment’s guide rails and drive system to ensure smooth and accurate cutting motion.

(2) Material

Secure Material: Before cutting, ensure that the material is securely fixed to the work table to prevent movement or vibration during the cutting process. Use clamps or fixtures to hold the material in place.

Check Material Flatness: For materials that are inherently uneven, perform preprocessing to make the surface as flat as possible before cutting.

(3) Operation

Set Cutting Parameters Properly: This includes cutting speed, cutting pressure, and cutting depth. Excessive cutting speed or pressure can result in uneven cuts. Refer to the equipment’s operation manual or experience data to set appropriate parameters based on the material and thickness.

2. Burrs and Camelback Bend

During the coil slitting process of metal raw materials, many processing centers encounter issues such as inconsistent cross-sections of the steel strip, with alternating cut and tear surfaces. This can result in large burrs and significant width tolerance variations, which are essentially manifestations of camelback bend. While such inconsistencies might not affect users with less stringent requirements, they can adversely impact high-precision and high-quality subsequent processing (e.g., high requirements for camelback bend in shelf manufacturing or issues like pitting from burrs in stamping). The situation worsens when cutting precision exceeds 0.1 mm.

The causes of these defects include:

(1) Damaged Coil Slitting Spacers

Parallelism Tolerance: The parallelism tolerance of the slitting spacers is ±0.002 mm. Visible damage or minimal errors exceeding 0.1 mm can impact cutting precision and quality. Damage to spacers typically results from improper handling or collisions during transport. Additionally, the material and surface hardness of the spacers are crucial; cost-saving measures on spacers might lead to precision issues. Therefore, careful selection and procurement of spacer materials are essential.

(2) Blade and Spacer Locking Issues

Ensuring Proper Locking: To ensure product dimensions, the coil slitter usually combines the blade shaft and blades into a complete unit. If all blades and spacers on the shaft are not properly locked, external forces from the strip steel can cause the blades to move with the shaft, resulting in burrs. The solution is simple: ensure proper locking. The effectiveness of locking methods (hydraulic vs. mechanical) is crucial. Mechanical locking, while convenient, may be less effective and requires strong operators. Hydraulic nut locking is more effective but requires knowledge of the equipment; improper selection might be less effective than mechanical locking.

(3) Non-Parallel Blade Frames

Parallelism of Upper and Lower Frames: Cutting is performed by the cooperation of the upper and lower blade frames. If these frames are not parallel, or if one is tilted, it can cause camelback bend and burrs. Correcting frame parallelism is relatively straightforward and can be quickly resolved by adjusting the worm gears and using specialized detection equipment.

If the above methods do not resolve the issues with the coil slitter, it is advisable to contact the relevant manufacturer or maintenance personnel for further inspection and repair.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima