What is the Function of a Slitting Machine?

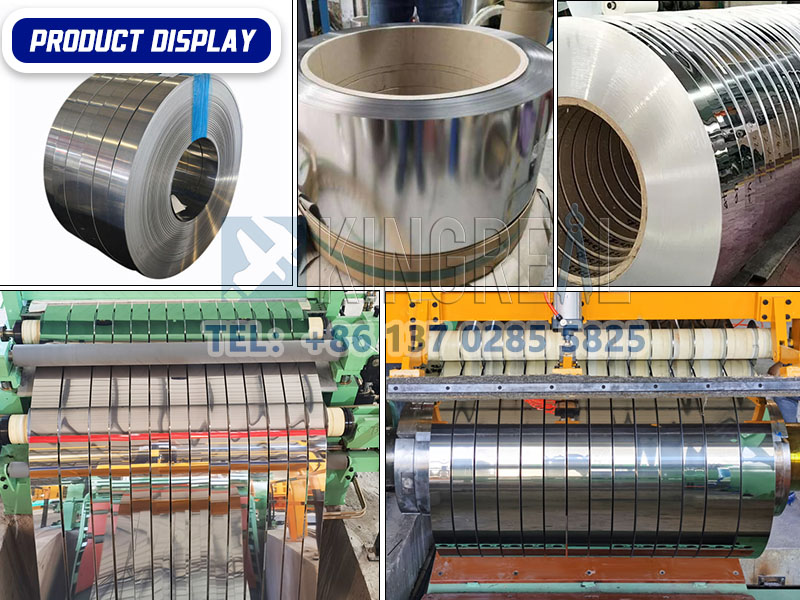

A coil slitting machine is a commonly used piece of industrial equipment designed to cut materials into multiple smaller pieces or narrow strips. It is widely used across various industries for cutting materials such as paper, plastic, and metal, significantly enhancing production efficiency and quality. KINGREAL is a specialized slitting line machine manufacturer. If you have any questions, feel free to consult with us! This article will provide a detailed overview of slitting line machines.

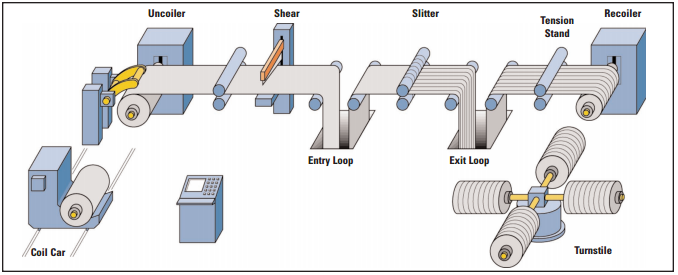

Working Principle

The working principle of a coil slitter is both ingenious and efficient.

It begins with an automatic feeding system that introduces the raw material into the machine.

Then, the cutting mechanism, based on preset parameters, performs precise cutting to divide the material into strips of the desired width.

Finally, the collection mechanism gathers these cut strips for subsequent processing.

It begins with an automatic feeding system that introduces the raw material into the machine.

Then, the cutting mechanism, based on preset parameters, performs precise cutting to divide the material into strips of the desired width.

Finally, the collection mechanism gathers these cut strips for subsequent processing.

Precautions

1. Ensure Correct Voltage and Settings: Before starting, verify that the voltage, current, and hydraulic values are correct and stable.

2. Safety Precautions: Before the machine starts, ensure that all personnel are notified and have left the vicinity of the equipment to avoid any personal injury.

3. Avoid Contact with Moving Parts: Do not touch moving rolls or cores during operation to prevent personal injury from getting hands caught.

4. Protect the Equipment: Avoid using knives or hard objects that could scratch or damage the rolls during operation.

Functions

1. Increased Production Efficiency:

Coil cut to length machines can significantly improve production efficiency. Traditional manual slitting requires substantial labor and time, whereas coil slitting equipment offer automated operation,

high-speed slitting, and continuous working, greatly reducing labor costs and boosting production efficiency. This is crucial for businesses as it helps save on production costs and enhance operational efficiency.

high-speed slitting, and continuous working, greatly reducing labor costs and boosting production efficiency. This is crucial for businesses as it helps save on production costs and enhance operational efficiency.

2. Precision and Consistency:

Coil slitting cutting machines ensure high precision and consistency in slitting work. While manual slitting can be prone to errors, slitting machines can precisely control cutting positions and dimensions, ensuring the quality and uniformity of each strip. This enhances the product’s market competitiveness.

3. Flexibility and Multi-functionality:

Coil cut to length machines are highly flexible and can be adjusted to meet different product requirements. They are suitable for slitting various shapes and sizes of materials. Moreover, a single slitting machine can handle multiple specifications and types of products, improving the flexibility and versatility of the production line.

4. Energy Efficiency and Environmental Benefits:

The development of automated equipment aligns with modern production demands, greatly reducing energy consumption and minimizing waste production. In today’s society, where environmental protection and sustainability are emphasized, using slitting machines can help companies gain more market recognition and a positive reputation.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima