How to deal with the edge burr problem of the coil slitting machine?

There are many problems in the operation of the metal slitting machine. These include poor edge quality, edge burrs, edge waves, arcs, crossbows, knife marks and out-of-spec slit widths. These are some problems that will inevitably arise as the number and time of use of the machine increase.

When you find a problem with the machine, you can choose to contact the supplier as soon as possible. For example, the manufacturer of KINGREAL will provide you with after-safes service in time. In addition to understanding the cause of the problem can also improve the ability to deal with emergencies.

.jpg)

Quality tools ensure good settings, controlled edges and long tool life. If you have a slitting problem and suspect your tool is causing it, check it for damage or have it checked by a reputable manufacturer.

Still, the best tool isn’t everything. If the machine is not maintained, the bearings are loose, or the shoulder is damaged, you will still get bad results. Expert training and inspections can help.

The following will introduce you to be the reasons for the burrs:

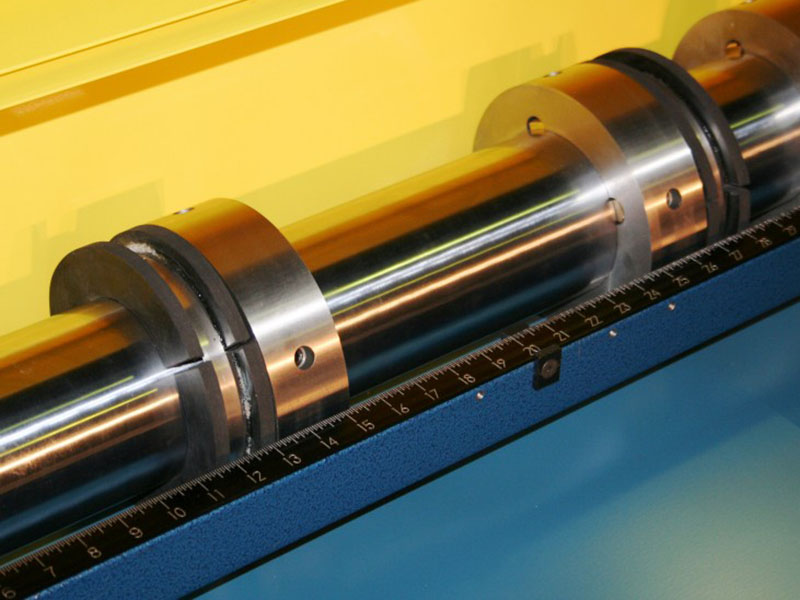

Burrs are edge defects that can occur during the slitting process. The main cause of burrs is that the horizontal knife gap is too tight or too loose. Incorrect gaps automatically result in poor quality edges. In fact, one of the hallmarks of poor quality edges is burrs.

If the horizontal gap is too loose, the metal will stretch around the knife and tear. These lightweight spacers are designed to be easier to lift and handle during installation than solid metal spacers.

If the horizontal gap is too tight, more force is required to cut the material. The only way to apply more force is to lower the tool, which creates burrs.

In addition, dull knives automatically produce burrs. The material wraps around the obtuse corner of the knife and weeps. Therefore, it is very important to use the correct knife for your slitting needs. A knife that dulls too quickly can cause burrs.

On the other hand, if the knife shatters because it is too brittle, you will need to reset it and you will waste time. It’s best to use the most wear-resistant knife so that the edge stays sharp for the longest time. The less control you have over the setup and machine, the stronger the tool must be.

Setting a vertical knife gap that is too deep (too much overlap) can also cause burrs.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima