The Advantages of Coil Perforation Line

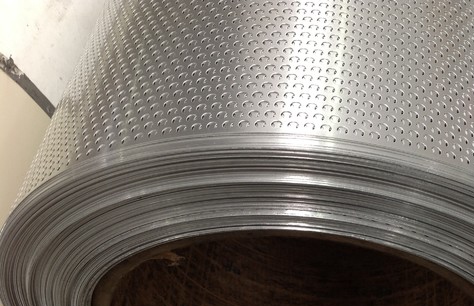

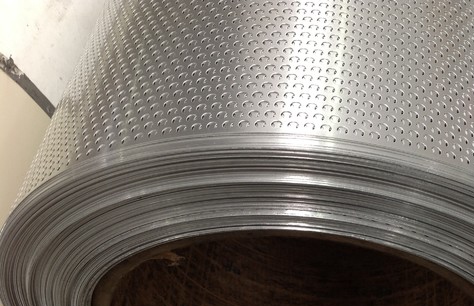

With the development of modern manufacturing industry, coil perforation line has become one of the indispensable equipments in the production line. It plays an important role in metal processing and other manufacturing processes, and has a profound impact on the productivity and production quality of an organization. To help manufacturers increasing productivity, the professional technical team of KINGREAL provided a complete solution that combines a perforation machine and a coil slitting machine into a coil perforation line. The following are some key aspects of the role of coil perforation line in production and their impact on businesses.

Effect on production:

1. Automated production: Coil perforation line can perform perforating and coil slitting tasks continuously and efficiently through automation. This reduces the need for manual intervention, reduces human error in the production process and increases productivity.

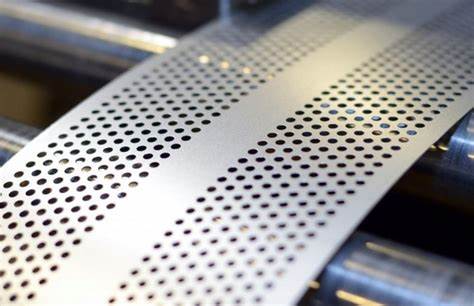

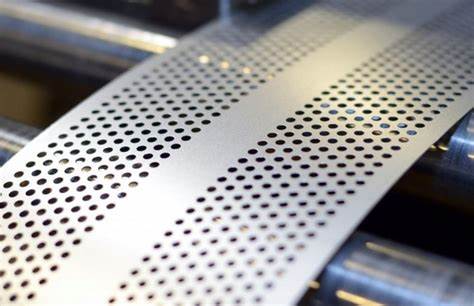

2. Accuracy and Consistency: These machines are able to perform perforating and coil slitting tasks with precision, ensuring quality and accuracy of the finished product. KINGREAL coil perforation line is controlled by PLC, featuring high degree of automation, high punching precision and good slitting quality.This is critical in manufacturing, especially in industries that require high precision parts, such as aerospace, automotive and electronics manufacturing.

3.Time and cost savings: The automation and efficiency of coil perforation line means faster production processes and reduced cycle times, which reduces production costs. Reducing scrap and secondary processing also saves on material and labor costs.

4.Improved safety: Automated production reduces the risk of workplace accidents by reducing employee contact with the machine. This helps to improve job security and employee safety.

5. Flexibility: Perforation machine and coil slitting machine can usually be set up and adjusted as needed to meet the requirements of different workpieces. This improves the flexibility of the production line and enables companies to respond flexibly to changes in market demand.

The impact on enterprises:

1.Increased competitiveness: The operation of KINGREAL coil perforation lin is easy, you just need to set the parameters on the electronic control system than the machines can punch and slit automatically. By improving productivity and quality, enterprises can gain a competitive advantage in the marketplace. This helps to attract more customers and orders.

2.Reduced production costs: automated production and reduced scrap means lower production costs, improving the profitability of the business.

3. Increase production capacity: the high efficiency of the perforation machine and coil slitting machine allows companies to produce more products in a shorter period of time to meet market demand.

In conclusion, coil perforation line play a key role in modern manufacturing and are essential for increasing productivity, reducing costs and improving product quality. Businesses investing in these machines can reap long-term rewards, contributing to competitiveness and sustainable growth.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima