KINGREAL is a professional metal coil processing manufacturing machine supplier that can provide Belt Tension Coil Slitting Machines, which is the best choice for coil processing.

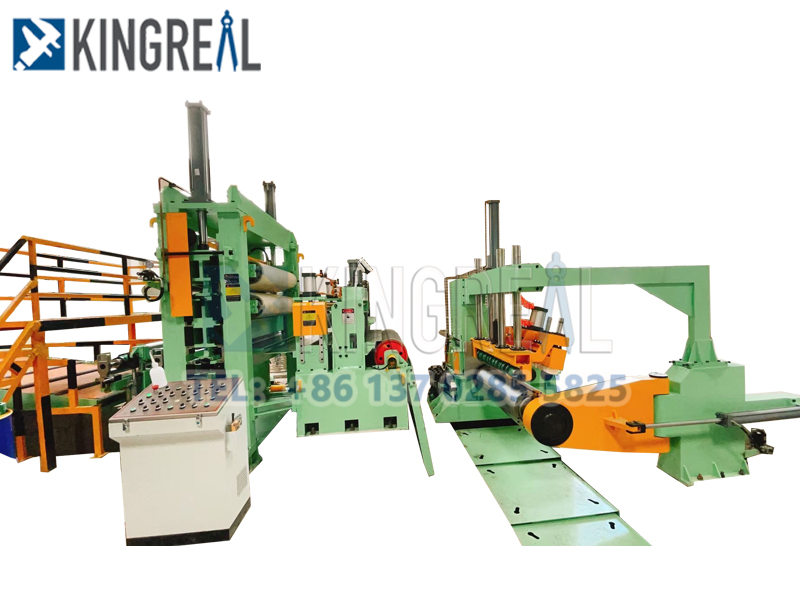

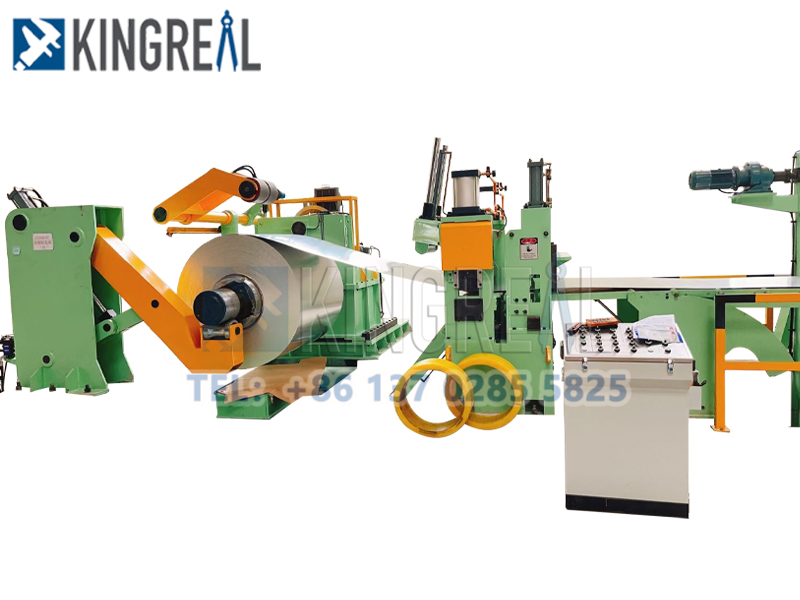

| Belt tension slitting line machine is for material 3mm thick,max.1600mm width of coil, with speed 180m/min,cutting strips 30 pieces. This line is the best choice for coil processing center users. The whole coil slitting line is controlled by PLC with a computer display. We mainly apply a computer-control system of brands Mitsubishi, Yaskawa, Siemens, Baumueller, Delta, and Schneider. The information on order amount, cutting strips and speed can be input to the PLC systems. Belt tension coil slitters use belt bridles, which is a higher cost performance for customers with precision surface requirements. |

|

![]() KINGREAL Successful Coil Slitting Machine Projects

KINGREAL Successful Coil Slitting Machine Projects

![]() Main Components of Slitting Machine

Main Components of Slitting Machine

|

1.Coil car 2.Decoiler 3.Peeler entry table 4.Straightener. 5.Shearing machine 6.Loop table 7.Coil guide and pinch roll 8.Slitting machine 9.Scrap winder (both sides) 10.Loop table 11.Separator and tension table 12.Deflector roll and exit threading table 13.Recoiler 14.Over arm separator in the recoiler. 15.Exit coil car for recoiler 16.Hydraulic system 17.Pneumatic system 18.Electrical control system |

|

![]() Why You Need a Belt Tension Unit

Why You Need a Belt Tension Unit

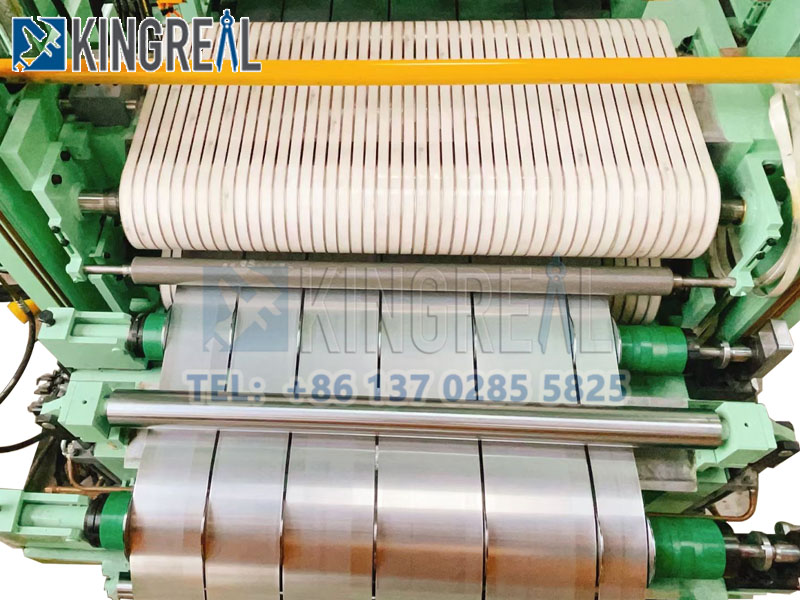

Belt Tension Unit is mainly used for coil slitting lines that require high scratches free on the strip surface, such as stainless steel, silicon, color coated and aluminum coils.

Belt Tension Unit is a combined design of Belt bridle and felt pressing interchangeable type, the steel strip is pressed by the upper and lower belts or felts to generate friction and provide tension for the recoiling.

Belt Tension Unit with special multiple belts and stretched individually and differently through the idler, so that the slitter strips can be recoiled with equal tension. The tension adjustment is done by adjusting the hydraulic depressing cylinders.

![]() Advantages of Belt Tension Coil Slitter

Advantages of Belt Tension Coil Slitter

2. The belt and strips are relatively rested during recoiling, so there is no scratch on the surface of the strips.

3. Combined design or belt bridle and woolen felt pressing type, raise or lower for interchange in the same frame.

|

|

4. The special endless belt is directly installed on the idler wheel with a circulating cooling device inside, which can keep the cooling state for a long time.

5. According to type and thickness of the input material, the tension can be adjusted by changing cylinder pressure, which is easy to operate.

![]() Working Parameter of KINGREAL Belt Tension Coil Slitting Machine

Working Parameter of KINGREAL Belt Tension Coil Slitting Machine

| Max. width of coil : 1600mm Slitting speed : 180m/min Max.cuslitting strips : 30 pieces |

|

![]() Reference Data

Reference Data

|

Raw Material |

Galvanized steel, stainless steel or SS |

|

Thickness |

0.15-0.8mm |

|

Coil Width |

Up to 1600mm |

|

Motor Power |

4.5kw |

|

Max Cutters Pieces |

According to client‘s coil width exact width |

|

Efficiency |

3 to 4 tons /day |

|

Power Source |

3xAC380V, 50HZ |

|

Main Machine Dimension |

2600*1200*1200 mm |

|

Weight |

800KG |

|

Application |

Slitting Galvanized steel, stainless steel |

![]() Other Featuring Coil Slitting Machine in KINGREAL

Other Featuring Coil Slitting Machine in KINGREAL

| Dual Slitter Head Coil Slitting Machine Hot Roll Coil Slitter Heavy Gauge Slitting Line Machine Thin Plate Coil Slitting Machine |

|

![]() Kingreal Factory

Kingreal Factory

To integrate R&D, KINGREAL has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of our customers also choose to visit our factory to observe the production of machines and communicate with us face to face. We are looking forward to reaching long-term and stable relationships with customers around the world with our professional capability and consistent level of service!

![]() Customer Visit

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL warmly welcomes customers to visit our factory and communicate with us!