What is cutting processing of cut to length machine?

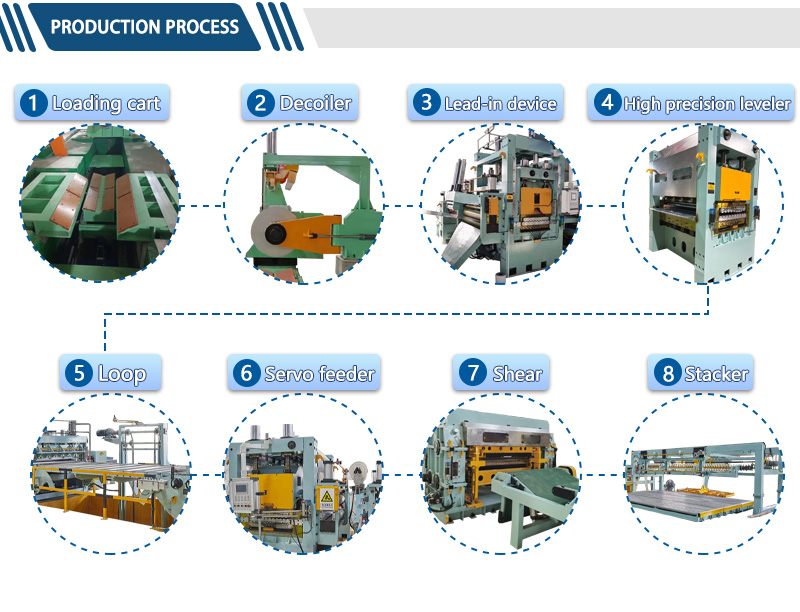

Main components and processing of cut to length line:

1. Feeding device: feeds metal sheets or coils into the cut to length line.

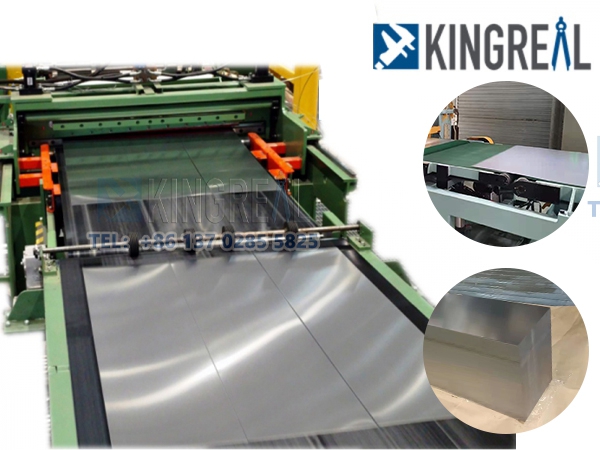

2. Cutting unit (cut-to-length machine): core equipment, shears metal sheets or coils horizontally through knives.

Application of shearing production line:

1. Metal processing industry: for cutting cold-rolled plates, hot-rolled plates, galvanized plates and other metal materials to a fixed length. KINGREAL metal cut to length machine is compatible with a variety of metal raw materials, which can meet your different requirement of metal cut to size.

2. Manufacturing industry: widely used in automobile manufacturing, building materials processing, metal component manufacturing and other fields.

Factors to consider when purchasing a metal cut to length line:

1. Cutting requirements: Select a suitable metal cut to length line based on the type, thickness and size of the metal material to be cut. You can contact us and tell us your needs of metal cut to size. Kingreal has more than 20 years of experience in metal cut to length line manufacturing and can design and customize metal cut to length line according to your production needs.

2. Production capacity: Select equipment of appropriate specifications based on the production capacity and efficiency requirements of the metal cut to length machine.

|

|

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima