What is precision press stamping?

Precision stamping refers to various materials punched out by precision punching machines. These precision stamping parts themselves have higher precision requirements than ordinary stamping, such as terminal pieces, USB interfaces, motor stators and rotors, air conditioner fins, EI sheets, etc. Large quantity, high product precision requirements.

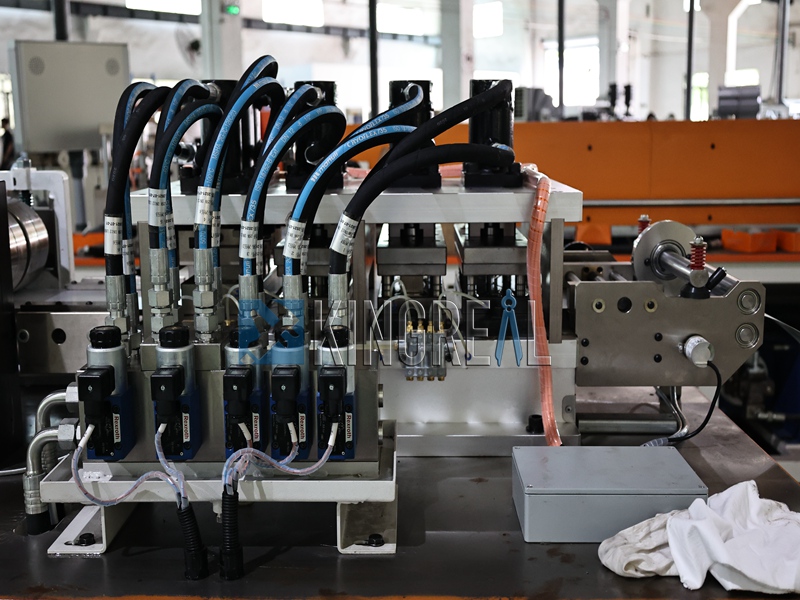

In the production process of precision stamping parts, stamping coils or forming, must consider the appropriate technical support of precision punching machines, molds, materials, lubricants, etc.

Precision stamping needs to be produced by a precision punch. The structure, pressure effect and safety device of the punch have the following requirements:

1. High rigidity in vertical and horizontal directions

2. The mold installation table, when installing the mold gasket, the deformation is very small

3. It is easy to achieve the best working condition

4. There must be measures to prevent mold damage

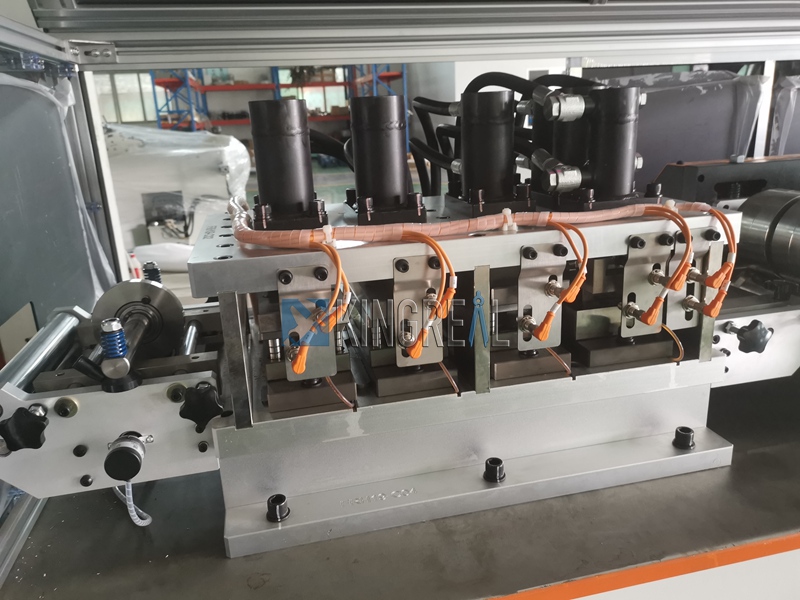

The construction of the mold is not only required to be simple and light in weight, but also suitable for use. When processing thick plates, for molds that are prone to deformation, there is no obvious deformation due to the use of center support.

Even during blanking, when the workpiece is squeezed into the die, if the ejector retreats, the inside of the die is supported by the center support.

If the hydraulic piston is connected to the side of the ring gear pressure plate, and the piston retreats, the inside of the die ring gear pressure plate side is still supported by the center, so the rigidity will not be destroyed at any time.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima