What is the slitting process?

A coil slitting machine is a common piece of machinery used to cut raw materials into desired strip products. KINGREAL is a professional slitting machine manufacturer. If you have any questions, feel free to consult with us! Many people are curious about the specific slitting process, so this article will give you an overview.

Principle of Slitting

To understand the working principle of the slitting process, we need to delve into its basic principles:

Shearing Action: Slitting is essentially a shearing operation. Metal sheets are cut longitudinally by a set of rotating blades, similar to the working principle of scissors.

Width Control: The distance between the blades determines the width of the slitted coil. Therefore, precise blade positioning is crucial for achieving the desired width.

Tension Management: Proper tension management is essential for maintaining the flatness and edge quality of the slitted coils. Incorrect tension can lead to issues such as camber (bending of the strip), burrs, or wavy edges.

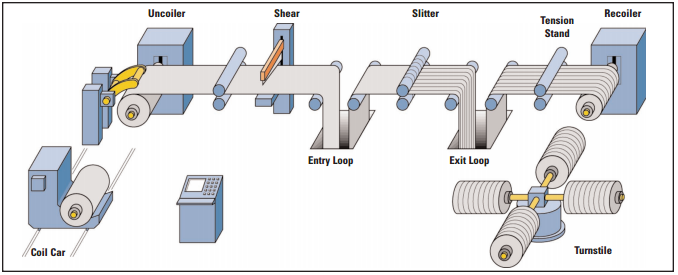

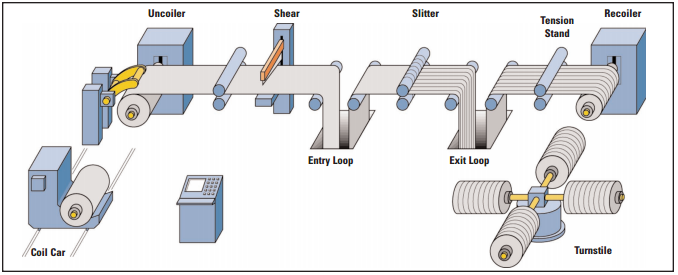

Components

A coil slitting line consists of a long station, including an uncoiler, slitting machine, and recoiler. Each part of the coil slitting machine is responsible for handling the metal sheet, which is fed into or out of the station via conveyors.

Uncoiler: Also known as a decoiler, this is the first part of the machine. It allows the metal coil to be unwound into metal sheets for the coil slitting machine. Proper setup of the uncoiler significantly impacts the success of the slitting process. Parameters such as weight, width, thickness, inner diameter, outer diameter of the metal coil, and delivery speed need to be considered. Failure to meet these requirements can lead to a complete failure of the slitting process.

For example, if the discharge speed of the metal coil is faster than the coil slitting machine‘s ability to cut the metal sheets, the metal sheets may not remain flat, causing camber on the metal coil. Therefore, correctly setting up the uncoiler is the crucial first step in the slitting process.

Slitting Machine: This is the section with the cutting blades in the middle of the production line, which performs the second operation after the metal sheets are uncoiled. The slitting machine consists of a series of circular blades arranged in a row. Once the metal coil is unwound into sheets, they are fed to the top of the slitting machine for cutting.

Thus, the total width of the metal sheets equals the series of blades, and the spacing between each circular blade determines the width of the final product, which is the narrower metal coil. Similar to the uncoiler, even small deviations in the coil slitting machine setup can greatly affect the final product. For example, the total width of the metal sheets should match the total width of the blade series. If the metal sheets are narrower, they might not fit perfectly on the blades or could become distorted. Conversely, if the metal sheets are wider than the blade series, they cannot be fed into the slitting machine for cutting. Moreover, the spacing between each circular blade should be evenly distributed, as it determines the width of the cut coils. Ensuring evenly spaced blades before cutting is crucial to avoid inconsistent product sizes.

.jpg)

Recoiler: The recoiler is the final part of the slitting machine where the cut metal coils are wound back into coils. After the final product is made, it needs to be recoiled, which is assisted by the recoiler. The recoiler‘s function is opposite to that of the uncoiler, and similar parameters need to be followed, including the weight, width, thickness, inner diameter, outer diameter of the metal coil, and the delivery speed.

Workflow

Unwinding Metal Sheets: As the name suggests, this process occurs on the uncoiler. When the wide metal coil is set with consistent width, inner diameter, outer diameter, and speed around the uncoiler, it will begin to release the metal sheets onto the conveyor, which then transports the sheets to the slitting machine.

Cutting Metal Sheets: Once the metal sheets are unwound and transported by the conveyor to the slitting machine, a series of sharp circular blades set beneath the metal sheets will begin cutting them. Besides adhering to the parameters for the uncoiler, the cutting motion is determined by the compressive force provided by the slitting machine. When the metal sheets are fed onto the blades, the slitting machine applies a compressive force to push the metal sheets for cutting. Once this force is applied, the metal sheets are cut into narrower coils based on the spacing between the blades.

Rewinding: After the metal sheets are cut into narrower coils, they are transported by the conveyor to the final station of the slitting machine, the recoiler. Upon receiving the metal coils, the recoiler helps wind them back into coils, completing the final product. The delivery speed of the coils is crucial here. Since the coils are already cut into thinner sections but still long, the speed at which these coils are delivered to the recoiler will determine the quality of the final coils. Thus, it is important to have operators monitor and adjust the machine during the slitting process to ensure it runs smoothly without issues.

Conclusion

By understanding the working principles and components of a coil slitting line, we can gain a better grasp of the operation process of this crucial piece of machinery. Accurate setup and operation of the slitting machine are essential for ensuring the quality of the final product. From unwinding to slitting and recoiling, each step requires meticulous control and monitoring. We hope this article helps you better understand the mechanisms and operational points of slitting machines. If you have any questions or need further information about slitting machines, please feel free to contact us, and we will be happy to assist you.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima