What is the use of slitting machine?

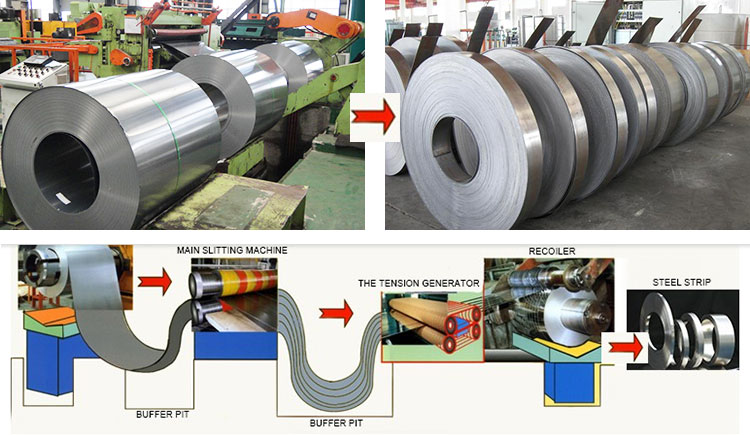

A coil slitting machine is a commonly used industrial device designed to cut wide rolls of material into narrower strips. This process is known as "slitting." Slitting machines are used in various industries, including metal, plastic, paper, and textiles. KINGREALis a professional slitting line manufacturer. If you have any questions, please come to consult! This article will explore the purposes and significance of the coil slitter in detail.

.jpg)

1. Ensuring Consistency in Material Specifications

One of the primary purposes of a slitting line machine is to cut large-width materials into sizes that meet customer specifications. Different industrial applications require materials of different widths. By slitting, manufacturers can produce materials of predetermined widths and lengths based on market demand and customer requirements. This not only ensures consistency in product specifications but also improves production efficiency and reduces waste.

2. Enhancing Production Efficiency

In many production lines, processing wide rolls of material can be time-consuming and may lead to production bottlenecks. Using a coil slitting equipment to pre-slit materials into suitable widths can significantly enhance the efficiency of subsequent processing stages. Slitted materials are easier to handle, store, and transport, optimizing the overall production process.

3. Meeting Diverse Market Demands

As market demands for product specifications and sizes diversify, companies need to be able to quickly adjust their production lines to accommodate different needs. The use of coil slitting cutting machines allows production lines to rapidly adjust and produce materials of varying specifications to meet diverse market requirements. This flexibility is a crucial feature of modern manufacturing.

4. Improving Material Utilization

In many production processes, large-width raw materials often result in waste. Precision slitting with a coil cut to length machine can maximize the use of raw materials and minimize waste generation. Efficient slitting not only reduces production costs but also aligns with environmental sustainability efforts by reducing the environmental footprint.

5. Enhancing Product Quality

The precise cutting technology of slitting machines ensures that the cut edges are smooth and even, avoiding defects that may occur with manual cutting methods. This high-precision slitting technology helps improve the quality of the final product, ensuring that each strip of material is consistent in size and shape, meeting stringent quality standards.

6. Adapting to Various Processing Needs

Slitting machines can handle a wide range of materials, including metal coils, plastic films, paper, and textiles. This versatility makes slitting machines widely applicable in different industrial sectors. Whether for automotive manufacturing, packaging, or electronics production, slitting machines provide tailored solutions based on material characteristics and processing requirements.

7. Saving Storage and Transportation Space

Large-width rolls of material often occupy significant space during storage and transportation. By slitting these materials into suitable sizes, storage and transportation space can be conserved. Additionally, slitted materials are easier to manage and distribute, further enhancing logistics efficiency.

In summary, slitting machines play a vital role in modern manufacturing by ensuring material consistency, improving production efficiency, meeting diverse market demands, optimizing material use, enhancing product quality, adapting to various needs, and saving storage and transportation space. Their versatility and precision make them indispensable in many industrial applications.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima