Why is slitting necessary?

The coil slitting machine is used to unwind, slit, and rewind metal coils into desired widths. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and various metal materials with surface coatings or plating. KINGREAL is a specialized slitting line machine manufacturer. If you have any questions, feel free to consult with us! This article will discuss in detail why slitting machines are essential.

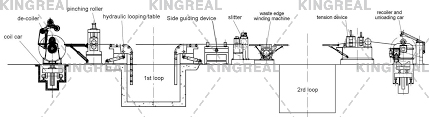

Process Flow

Loading Trolley -- Decoiler -- Roller Feeding -- Loop -- Slitting -- Waste Wire Machine -- Loop -- Separator -- Winder -- Unloading Car

Precautions

When using a coil slitting machine, there are important details to consider to ensure operational safety and increase efficiency. Here are some key points to pay attention to:

(1) Equipment Inspection and Maintenance: Before using the coil slitting machine, a thorough inspection of the equipment is necessary to ensure all components are in good working condition. Pay special attention to the sharpness and stability of the blades and the smooth operation of the transmission system. Regular maintenance is required to keep the equipment in optimal condition.

(2) Safety Measures: Strict adherence to safety procedures is mandatory when operating the coil slitter. The equipment should be placed on a stable surface to ensure stability. Operators should wear personal protective equipment such as helmets, safety goggles, and gloves. Avoid wearing loose clothing or having long hair that could become entangled in the equipment.

(3) Adjusting Work Parameters: During metal slitting processing, work parameters such as blade speed and feed rate should be adjusted according to the type and thickness of the metal material. Parameters that are too high or too low can affect cutting quality and equipment lifespan.

(4) Uniform Feeding: Ensure that metal materials are fed uniformly into the coil slitter to avoid issues like material breakage or deformation. Adjust the feeding system to ensure a stable and continuous feed into the cutting area.

(5) Cutting Quality Check: Monitor the cutting quality during the metal slitting process and conduct regular inspections. If cutting quality is poor, adjust the work parameters or replace the blades as needed. Avoid issues such as burrs, breakage, or uneven cuts.

(6) Scrap Handling: Metal slitting generates a significant amount of scrap, which should be cleaned and handled promptly. Scrap should be sorted for subsequent processing. Proper utilization of scrap can reduce resource waste and minimize environmental pollution.

(7) Operator Training: Operators must receive professional training and obtain relevant certifications before using the coil slitter. Only operators with the necessary skills and knowledge can handle the equipment proficiently and prevent accidents.

Importance of Coil Slitting Machine Cutting

(1) Providing Precise Specifications: During slitting, precise adjustments in cutting dimensions and quantities allow for the production of products that meet specific customer requirements. This customization ensures that the final product adheres to customer standards and usage needs, fulfilling various application scenarios.

(2) Quality Re-inspection: During the slitting and rewinding process, the large coils of metal raw material from the previous processing stage can be re-inspected for quality issues. The slitting operation not only reduces the large metal coils into smaller sizes but also provides an opportunity to check the surface, thickness uniformity, and coating quality of the metal material. This helps identify and correct any quality issues from the previous stage, ensuring that each coil meets quality standards.

(3) Defect Correction: Slitting can correct layer misalignment or remove parts with defects in printing and processing, improving the product grade. The process helps to identify and rectify misalignment or defects in the metal material, enhancing the appearance and performance of the final product while effectively reducing the rate of waste and customer complaints.

(4) Achieving Good Rewinding State: Through precise slitting operations, the final product coils can be wound with good coiling quality and stability. This not only facilitates better transport and storage but also avoids operational issues caused by uneven or loose coils, thereby improving production efficiency and product usability.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima