What is a Cut to Length Line?

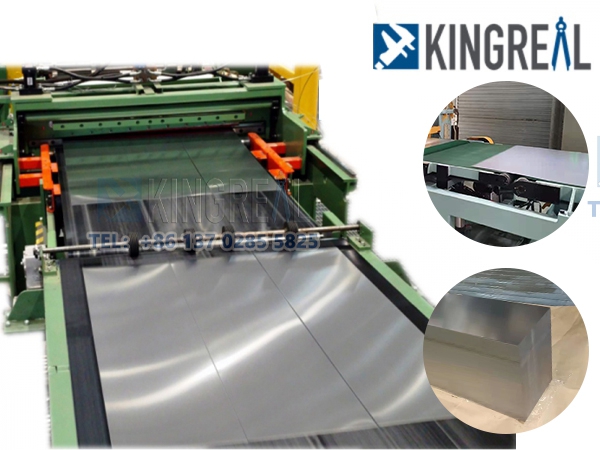

Cut to length lines are designed for sheet metal production by leveling and cutting a mother coil into cross sections, creating completely flat formats that are properly stacked. The basic process of cut to length lines comprises unwinding, levelling, cross cutting, stacking and packaging. The following kingreal will introduce the process flow and key technical points of cut to length line.

1.Overview

Profile cutting to length is a commonly used processing method in metallurgy, machinery, construction, aviation and other industries. It can cut long profiles to the required length according to the specified length, which is suitable for assembly, welding and other processes in production.

2. Process flow

(1) Preparation before cutting: set the cutting length on the equipment according to the length requirement of the profile, and check whether the blade and clamp of the equipment are stable to prevent error in the cutting process.

(2) Cutting operation: Place the prepared profiles on the machine, clamp them according to the requirements and start the machine for cutting. During the cutting process, it is necessary to pay attention to the running status of the machine and the cutting position in order to avoid problems such as cutting deviation or damage to the equipment.

(3) Post-cutting processing: Classify the cut profiles for subsequent processing such as welding, grinding or painting.

3.The key technical points

(1)Equipment selection: according to the characteristics of different profiles to choose the appropriate equipment to ensure cutting quality and efficiency. As a professional manufacturer of Coil & Sheet Process Equipment, kingreal can provide multiple types of cut to length machine line, such as Electric Plate Cut To Length Machine, coil cut to length line, Fly Shearing Cut-To-Length machine and etc., which can meet your diverse production needs.

(2)Working environment: keep the working environment clean and ventilated to avoid debris entering the equipment during the cutting process and affecting the normal work of the equipment.

(3)Maintenance of tools and fixtures: Regularly check and maintain the tools and fixtures of the equipment to ensure their stability and reliability and avoid errors.

(4)Operating skills: operators need to be professionally trained and master the correct operating skills and precautions to avoid safety accidents and quality problems.

If you want to get more information about cut-to-length machine, please do not hesitate to contact us!

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima