What is a perforated machine?

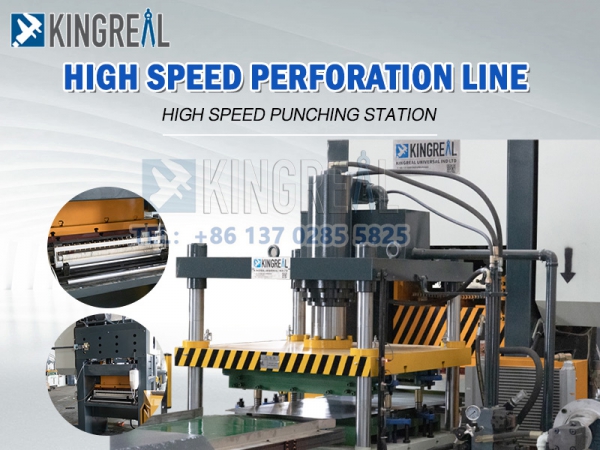

Punching machine is a kind of processing machine, is especially used for cold processing plate machine tools, can be punched through the punching die will be steel plate, stainless steel plate and other different materials of plate punching out various shapes of holes, used to make different parts, sheet, lighting, decorative materials, and so on.

The purpose of punching machine:

1. Metal sheet processing: Perforation machine is one of the most common machine and equipment for processing metal sheets. It can process metal sheets of various specifications and materials into different shapes. KINGREAL Metal Perforation Production Line is used for producing different kinds of perforation panel, raw material can be stainless steel, alloy aluminum etc..

2. Machinery industry: Many machines and equipment or mechanical parts need some special shapes of holes, perforated machine can be replaced by different punching molds to meet the needs of the machinery industry.

3. Architectural decoration: The processing range of metal punching machine is very wide, can process steel plate, aluminum plate and other metal materials, it can make all kinds of decorative materials, ceilings, blinds and other building materials.

4. Lighting: Perforated machines are also widely used in the lighting manufacturing industry and can produce various lighting casings, such as crystal lamps, metal lamps, etc.

Advantages of perforated machine:

1. High degree of automation: Punching machine can run the program to let the machine process automatically, which can not only improve the efficiency, but also reduce the labor intensity of workers. KINGREAL Metal Ceiling Tile Perforation Line is equipped with automated control system, realized the setting and adjustment of production parameters, as well as real-time monitoring and fault diagnosis of the production process.

2. High speed and high precision: Since the punching machine adopts the form of pressure support moment for processing, the speed is faster and the precision is higher, which can ensure the precision and quality of the products produced.

3. Low processing costs: Compared with the traditional mechanical processing methods, punching machine processing is more rapid and automated, can reduce production costs, improve production efficiency, and greatly enhance the competitiveness of enterprises.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima