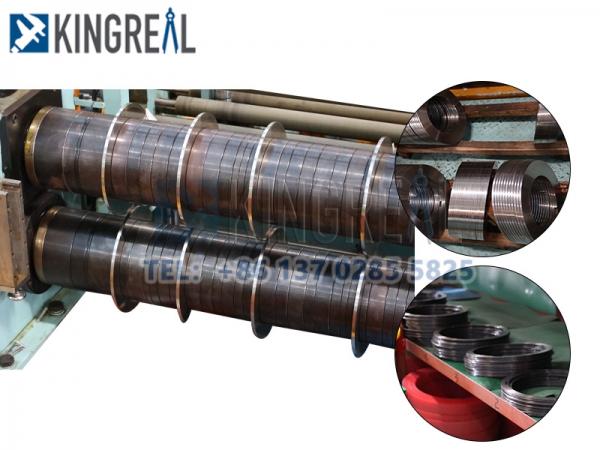

KINGREAL can provide the Slitter Blades, which is a cutting tool used in metal coil slitting machines for cutting metal coil or sheet materials.

![]() Description of Slitter Knife

Description of Slitter Knife

Slitting blades are used to slit coil into thin sheets or strips according to the required width. Slitter knives are one of the important parts of the coil slitting line. Using the right material and forging process is particularly important for a slitter knife. KINGREAL uses high-hardness raw materials and undergoes heat treatment to enhance the hardness and wear resistance of the slitter knife, allowing it to quickly complete a large number of cutting tasks, and making it more efficient in material handling in industrial production.

![]() Slitting Cutter Specification

Slitting Cutter Specification

| Round blade outer diameter | between 10mm and 1000mm |

| Round blade thickness | between 0.1mm and 80mm |

| Round blade material | a wide range of materials, such as high carbon steel, high-speed steel, tool steel, alloy steel, stainless steel, 65Mn, 9CrSi, Cr12MoV, SKD-11, skh-51, 2Cr13, 9Cr18, SUS440C, 420J2, W6Mo5Cr4V2, etc. |

![]() Main Features of Slitter Knife

Main Features of Slitter Knife

| - Wide compatibility Thickness up to 80mm, Outer diameter of up to 1000mm. The slitter knife of the coil slitting machine has a wide range of uses and can be used to cut a variety of metal coil materials. - Hard and wear-resistant KINGREAL uses high-hardness raw materials, such as 55SiCr, M6V, Cr12MoV, D2, SKD-11, H13, H13K, etc. After heat treatment, the hardness and wear resistance of the slitter blades are greatly improved, and the high-speed rotation and fast cutting capabilities of the slitter blades are greatly improved. - High Cutting Flatness The slitter knife design has been continuously polished and improved by KINGREAL‘s technical team, and the final slitter knife ensures a smooth and even cut without harming the surface of the metal coil, minimizing slitting resistance and improving the quality of the processed material. |

.jpg) |

![]() How to Get High Quality Slitter Blades

How to Get High Quality Slitter Blades

KINGREAL has its own manufacturing factory and technical team, providing customized coil slitting machine and equipment manufacturing services. You only need to send us the following information and KINGREAL can tailor a suitable metal slitter production plan for you:

1. Product size, including outer diameter, inner diameter and thickness

2. Metal coil material you need to slit

3. Metal coil thickness range

![]() What Kinds of Coil Slitting Machines can KIGNREAL Provide

What Kinds of Coil Slitting Machines can KIGNREAL Provide

KINGREAL has been deeply engaged in the manufacturing of metal slitters for more than 20 years and has accumulated rich experience in design, manufacturing, export and after-sales. KINGREAL can provide coil slitting line and their accessories. The following are some of the best-selling coil slitting machines of Kingreal:

KINGREAL can provide customized coil slitting machine manufacturing service, send us your production needs and KINGREAL will provide you with the latest technical plan.

![]() KINGREAL Coil Slitting Machine Projects

KINGREAL Coil Slitting Machine Projects

![]() KINGREAL Technical Team

KINGREAL Technical Team

KINGREAL is not only integrating R&D, has our own technical team and factory, but also has many years of experience in the design and manufacture of Coil Slitting Machine. KINGREAL has successfully customized Coil Slitting Machine lines to meet the needs of customers in many countries.

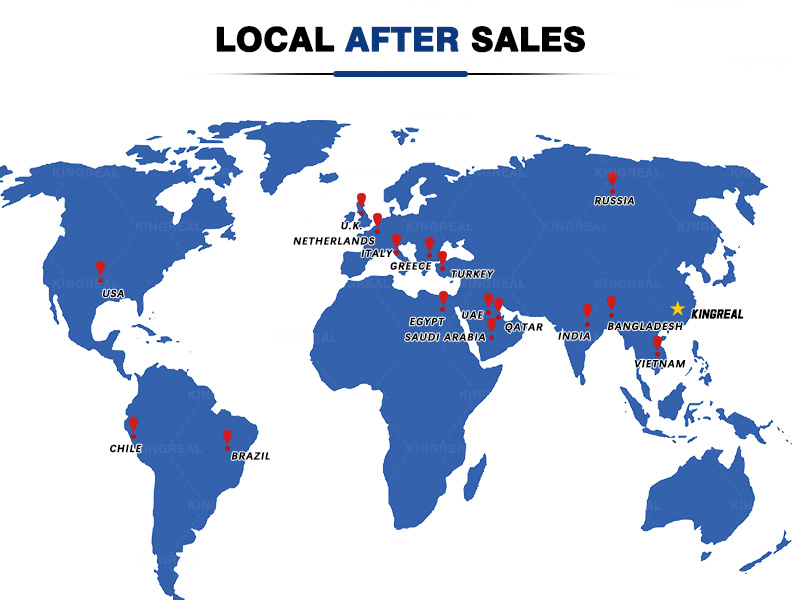

KINGREAL has established a localized technical support team in Indonesia, Brazil, Saudi Arabia, Canada, India and etc.. Localized service points in other countries are also in progress.

![]() Localized After-Sales Services

Localized After-Sales Services

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL has been insisting on doing. The global localization service point is under construction.