What are the problems with coil slitting?

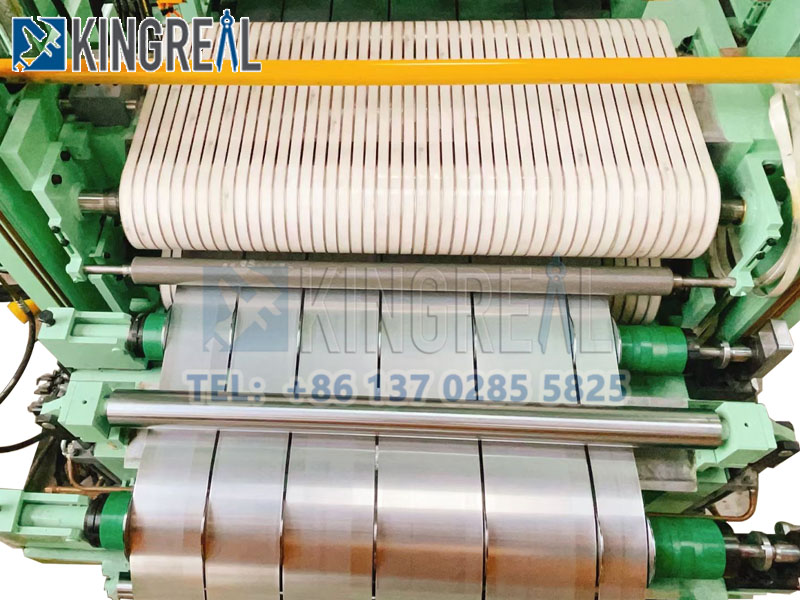

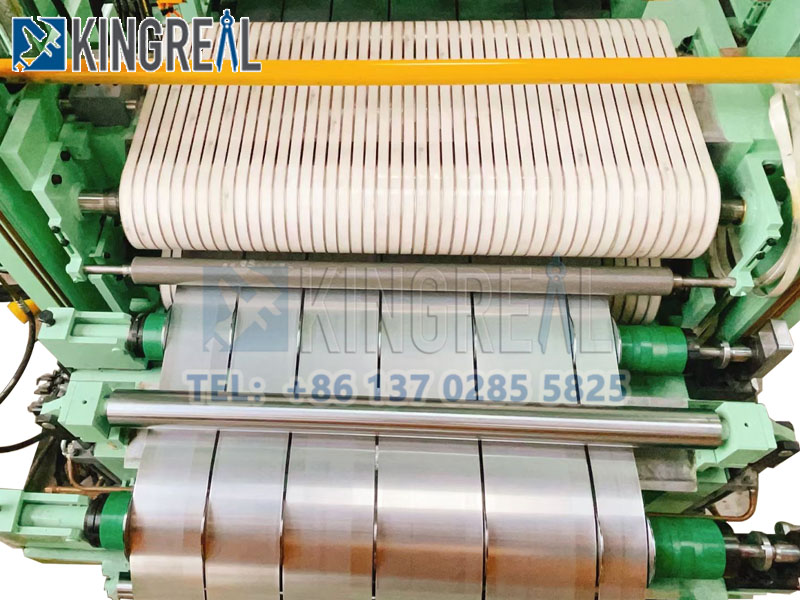

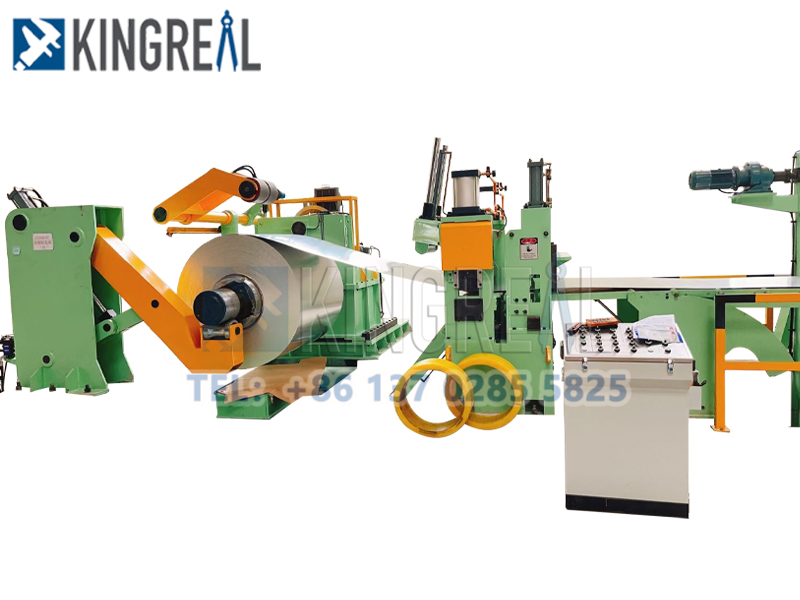

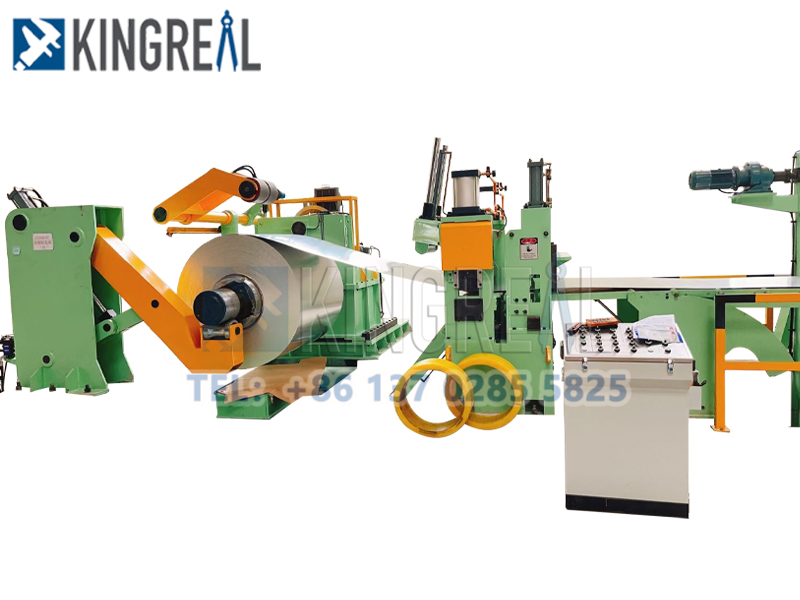

Coil slitting line is a common metal coil processing method, and its main function is to cut wide metal coils into narrow strips of required size. Horizontal and longitudinal shearing equipment usually adopts coiling device, which cuts wide metal coils into narrow strips by fixed length and fixed number of coils, and packs them according to standards for easy transportation and use.

Quality problems in coil slitting operation

During the steel slitting process, quality problems often occur, mainly in the following aspects:

1. Size does not meet the standard: Due to the inadequate metal coil slitter machine and coil slitting process, the size of the cut small plate may not meet the standard requirements.

2. Poor surface quality: During the coil slitting process, due to the inadequate equipment and mold, burrs, cracks, pitting and other defects are prone to occur on the surface, affecting the appearance and quality of the product.

3. Poor performance: During the coil slitting process, due to poor mold quality or improper equipment operation, the cut surface may be hardened too deep, bent, torn and other problems may occur, thus affecting the mechanical properties and service life of the product.

Causes of coil slitting operation volume problems

The main causes of coil slitting processing quality problems include the following aspects:

1. Equipment problems: The quality, accuracy and maintenance of the metal coil slitter machine directly affect the quality of the small plates cut out.

2. Mold problems: Unqualified or aging molds can easily cause deformation or damage to the surface and interior of the cut small plates.

3. Raw material problems: The quality of steel coil raw materials varies, and hidden defects such as excessive impurities or cracks will affect the quality of the product.

4. Operation process problems: Problems with the operation of the coil slitting line will also affect the quality of the product.

5. Abnormal noise or vibration: ① Transmission system failure: Check whether the transmission device is loose or damaged; ② Slide rail problem: Check whether the slide rail is clean and lubricate as necessary.

6. Electrical system failure: ① Cable connection problem: Check whether the cable is firmly connected; ② Component failure: Check whether the switch, sensor and controller are normal.

7. Control software problem: Check whether the control software needs to be updated

8. Unstable production: The coil slitting line lacks regular maintenance and does not implement regular maintenance plans.

Methods to solve the quality problems of coil slitting process

In order to avoid and solve the quality problems in coil slitting process, the following measures can be taken:

1. Selection of equipment and molds: Select appropriate metal coil slitter machines and molds according to the types and specifications of steel.

2. Maintenance of equipment and molds: Regularly check the wear and deformation of coil slitting lines and molds, and maintain and replace them in time.

3. Strict selection of raw materials: Quality inspection of raw materials, and selection of steel coil raw materials with good quality and no obvious defects.

4. Standardized implementation of operating procedures: Formulate strict operating procedures and standards to prevent operational negligence and errors.

5. Control of the processing process: Control the deformation and damage of metal coils during processing through processing parameter adjustment, auxiliary support, cooling, etc., to ensure the size and surface quality of the product.

6. Regular maintenance: Develop and implement regular maintenance plans to ensure the stable operation of the coil slitting line.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima