What is the purpose of a slitting machine?

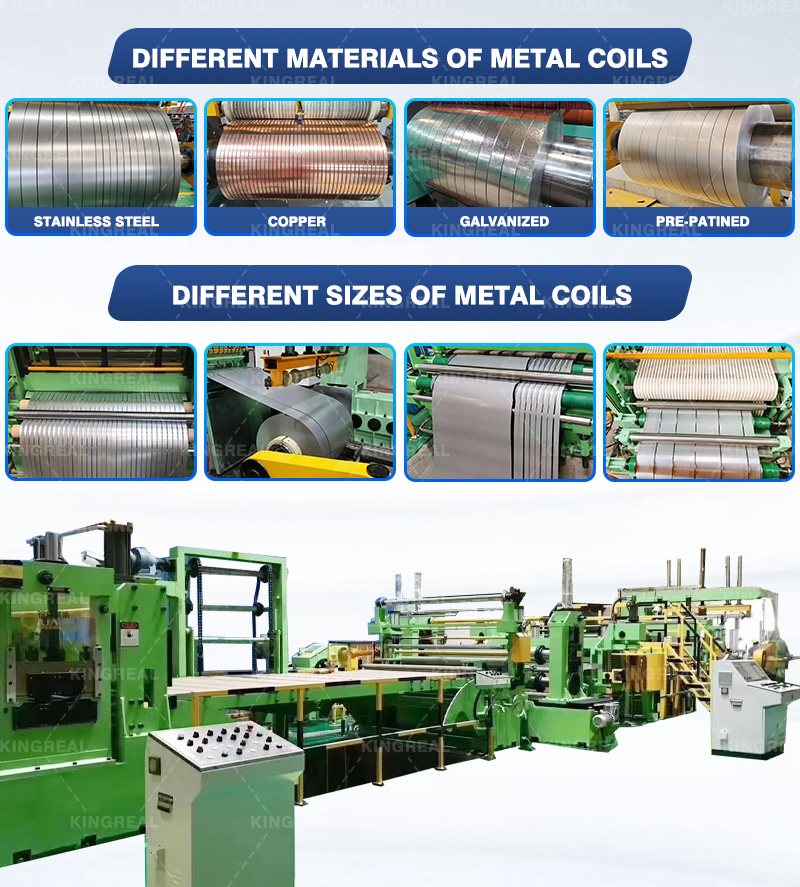

Slitting machine is also called coil slitting line, metal slitter, sheet metal slitting machine, which is used to unwind, slitting and rewind metal sheets or metal coils into narrow strips of required width. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating.

The working principle and components of the coil slitting machine

The working principle of the slitting machine is similar to that of a large pair of scissors. Its main function is to cut thick coils or plates into products of required length or size. The working process of the coil slitting machine generally includes the following steps:

1. Loading: Place the coil or sheet on the slitting machine.

2. Stretching: Stretch the coil or sheet with a mechanical drive.

3. Shearing: Shear the coil or sheet with a large blade in a standard position.

4. Collection: Collect the sheared material according to the specified length or size.

Coil slitting lines are usually composed of feeding mechanism, fixed length measuring mechanism, pulling mechanism, cutting mechanism, receiving mechanism and control system. Among them, the control system is the center of the entire production process, which ensures the automation of the entire process by real-time monitoring of equipment status, measuring product dimensions and controlling various operations.

Cutting to size

The purpose of slitting machine

Cutting to size

The metal slitter can accurately cut the width and length of various metal plates such as stainless steel plates, cold-rolled steel plates, hot-rolled steel plates, aluminum plates, etc. to meet the subsequent stamping, bending, welding, spraying and other process requirements.

Coil stripping

It is used to process continuous coiled metal strips (such as color steel coils, aluminum foil coils, etc.) and cut them horizontally into multiple narrow strips that meet the specification requirements. These strips will then be further processed into various metal products, such as home appliance housings, building materials, automotive parts, etc.

Integration of automated production processes

Efficient sheet metal slitting machines are usually integrated with automated production lines, which can automatically correct deviations, control tension and track precision, ensuring that the material is continuously, stably and accurately cut into multiple small pieces, greatly improving production efficiency and reducing waste.

High-quality cutting effect

The metal slitter is equipped with high-precision tools and an excellent drive system, which can ensure the quality of the slitting edge, without burrs or deformation, which is especially important for products with high surface quality requirements.

Diversified operation modes

According to different materials, thicknesses and customer‘s personalized needs, the sheet metal slitting machine can choose different cutting methods and tool types to adapt to the slitting of various metal materials from thin to thick, from soft to hard. KINGREAL also can customize metal coil slitting machine manufacturing plan according to your specific production requirements.

Fields of use of slitting machines

Coil slitting machines are widely used in various fields, such as steel and aluminum processing, building materials production, automated production lines, etc. In steel mills, auto parts manufacturers, home appliance manufacturers and other enterprises, slitting machines are widely used to produce plates, coils, aluminum plates, stainless steel coils, color-coated steel plates and other products.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima