What is a steel slitter?

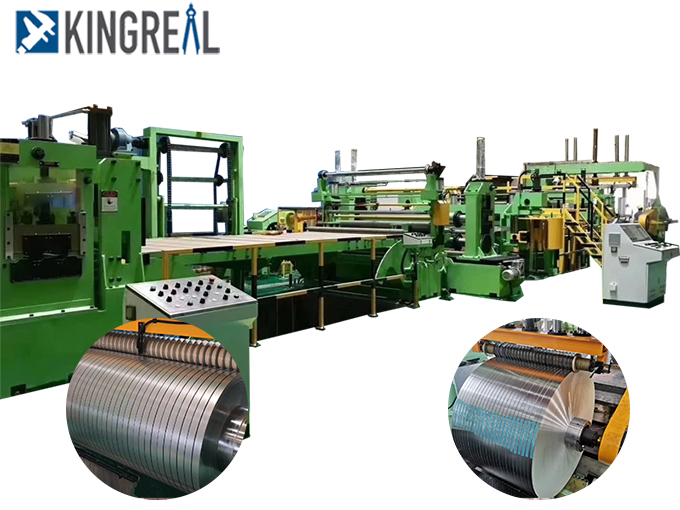

Steel slitter is a metal processing equipment, mainly used for cutting metal coils, strips, plates and other products. It can accurately control the length and shape of products by stretching, cutting, leveling and other operations on materials such as steel, aluminum, copper, etc., and is one of the most important equipment in the metal coil slitting operation industry.

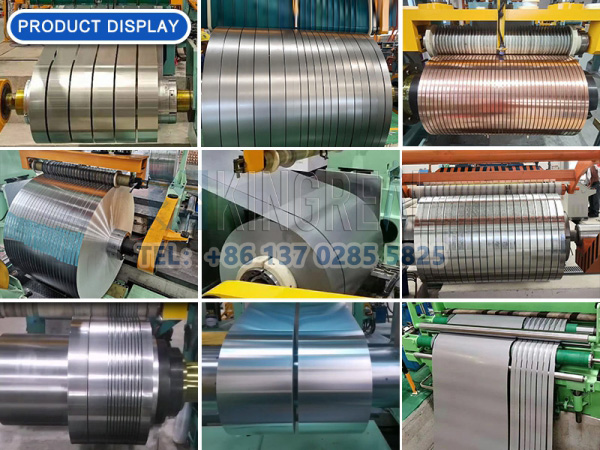

Steel slitter is widely used in various fields, such as steel and aluminum processing, building materials production, automated production lines, etc. In steel mills, auto parts manufacturers, home appliance manufacturers and other enterprises, slitting machines are widely used to produce plates, coils, aluminum plates, stainless steel coils, color-coated steel plates and other products.

1. Overview of coil slitting principle

Steel slitting machine is a commonly used steel coil slitting equipment, mainly used for shearing of steel and other metal plates. Its working principle is to shear the workpiece through the relative movement of the upper and lower cutter wheels. Among them, the upper shear slitter wheel uses the method of moving up and down to control the blade gap, and the lower cutter wheel is fixed on the machine body and moves along the track. When working, the steel slitting machine converts the movement of the motor into the relative movement of the upper and lower cutter wheels through the transmission system, thereby shearing the workpiece.

Steel slitting machine is a commonly used steel coil slitting equipment, mainly used for shearing of steel and other metal plates. Its working principle is to shear the workpiece through the relative movement of the upper and lower cutter wheels. Among them, the upper shear slitter wheel uses the method of moving up and down to control the blade gap, and the lower cutter wheel is fixed on the machine body and moves along the track. When working, the steel slitting machine converts the movement of the motor into the relative movement of the upper and lower cutter wheels through the transmission system, thereby shearing the workpiece.

2. The role of the slitter knives and the lower slitter knives wheel

The slitter knives of the longitudinal shearing machine is the key part to achieve the shearing of the workpiece. Its main function is to press the workpiece within a certain gap, so that the slitting surface of the workpiece undergoes plastic deformation, and on this basis, the workpiece is sheared. The lower slitter knives wheel is used to support the workpiece and help the slitter knives complete the shearing operation. When working, the lower slitter knives wheel realizes the automatic adjustment of the knife gap and the smooth movement of the workpiece by supporting the workpiece, thereby ensuring the slitter knives quality and slitting efficiency.

The slitter knives of the longitudinal shearing machine is the key part to achieve the shearing of the workpiece. Its main function is to press the workpiece within a certain gap, so that the slitting surface of the workpiece undergoes plastic deformation, and on this basis, the workpiece is sheared. The lower slitter knives wheel is used to support the workpiece and help the slitter knives complete the shearing operation. When working, the lower slitter knives wheel realizes the automatic adjustment of the knife gap and the smooth movement of the workpiece by supporting the workpiece, thereby ensuring the slitter knives quality and slitting efficiency.

3. Transmission mode

The transmission mode of the steel slitter usually adopts a transmission system composed of motor, reducer, transmission shaft and chain. The motor is responsible for providing power, the reducer can convert the high-speed power into a speed suitable for operation, and the transmission shaft and chain are responsible for connecting various components to achieve the coordination of the entire system. Through these configurations, the steel slitting machine can ensure shearing efficiency and cutting quality, and has reliable operating performance.

4. Slitter blades gap adjustment method

The slitter blade gap refers to the distance between the upper and lower slitter blade wheels of the steel slitter. This distance has a vital impact on the cutting quality. Therefore, when using the steel slitting machine for slitting, we need to pay attention to the adjustment of the slitter blade gap. The size of the slitter blade gap is usually determined by the thickness of the cutting plate and the hardness of the workpiece material. If the slitter blade gap is too large, it is easy to cause uneven cutting and surface burrs; if the slitter blade gap is too small, it is easy to cause problems such as excessive slitting force and increased wear of the slitter blade wheel.

5. Application areas of steel slitter

(1) Architectural decoration field

Steel slitting machines are widely used in the field of architectural decoration, such as the processing and customization of stainless steel plates, aluminum plates and other materials, mainly used for wall decoration, roof decoration, doors and windows and other projects.

(2) Electrical and electronic industries

Steel slitter is also widely used in the electrical and electronic industries, mainly used for the processing of various electrical components such as various equipment, appliances, and shells.

(3) Machinery manufacturing industry

Steel slitter is also widely used in the machinery manufacturing industry, mainly used to manufacture various mechanical parts, equipment and shells.

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima