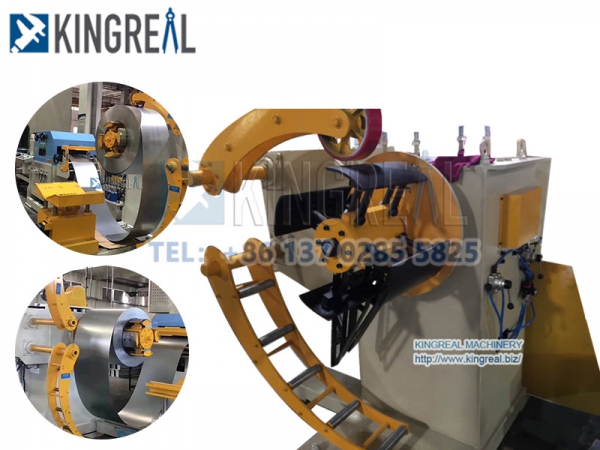

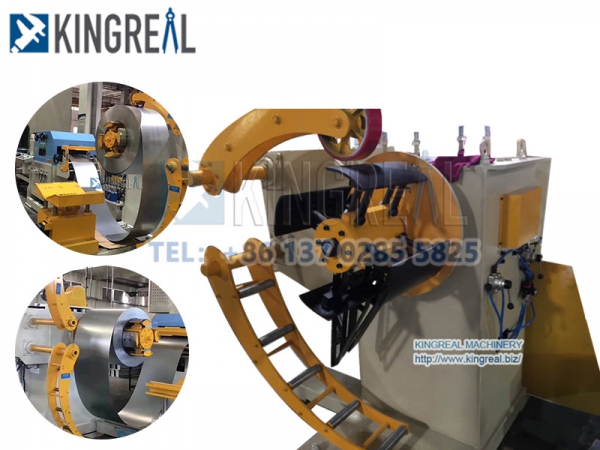

What is a Slitter Rewinder Machine?

A slitter rewinder is a machine dedicated to cutting a master or parent roll of material to a smaller width in order to process the material in the next steps of a production process. Slitter rewinders can be found in numerous types of manufacturing facilities in numerous types of industries across the globe.

The main features are as follows:

1. The machine head has a compact and reasonable structure and is easy to operate.

2. The cutting speed is adjustable, suitable for cutting and rewinding different materials to achieve the highest productivity.

The working principle is as follows:

1. The slitting machine needs to slit the entire roll or the entire sheet of raw materials to a fixed length, such as steel plates, leather, wood chips, etc., and must use fixed-length slitting control. For example, KINGREAL Narrow Strips Coil Slitting Machine is designed to accurately slit coils into narrow strips.

2. The cutting length can be set continuously. If there is an error in the actual cutting length, it can be easily calibrated by setting parameters.

Need to pay attention to the following during daily use:

1. Confirm that the maintenance work of the slitting and rewinding machine has been completed, the equipment is complete, and the maintenance personnel have moved out of the site.

2. Clean the debris on the walking platform, rack, operating table, equipment and other working surfaces, ensure that the equipment and working surfaces are clean and tidy, and comprehensively check whether the equipment is ready for startup.

3. Check the instruments on the console to see if the air source pressure is normal.

As a professional manufacturer of Coil Process Equipment, KINGREAL can provide a slitter rewinder solution, which make your production easier. If you want to get more information, welcome to contact us!

+86-137 0285 5825

+86-137 0285 5825  sales@kingreal.org

sales@kingreal.org jet-clima

jet-clima